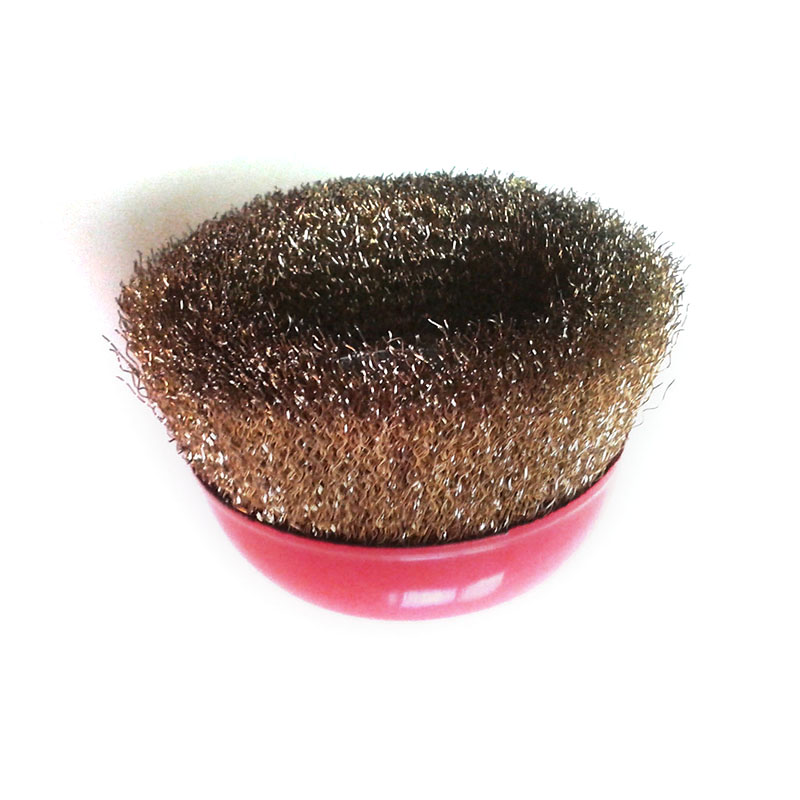

Cat:Wire Wheel Brush

The Twisted Wire Bowl Wire Brush is a powerful and durable cleaning and finishing tool designed for heavy-duty industria...

See DetailsReduced Heat Buildup Due to Open Structure

One of the key advantages of a Non-Woven Fiber Wheel is its open, flexible structure. The fiber mesh used in these wheels allows for increased airflow between the abrasive particles, which naturally dissipates heat during the grinding or polishing process. This open structure contrasts with traditional abrasive wheels, such as grinding wheels, which have a dense, compact design that can trap heat and increase friction.

The fibers in a Non-Woven Fiber Wheel are interwoven in a way that promotes better heat dissipation, reducing the potential for heat-related issues like surface burns or distortion. This ability to keep temperatures in check is particularly important when working with sensitive materials like aluminum, plastic, or thin metals, where heat buildup could cause unwanted changes in the material’s properties.

Consistent Abrasive Action Reduces Frictional Heat

The abrasive action of a Non-Woven Fiber Wheel is more consistent and less aggressive than that of traditional grinding wheels. This allows for smoother material removal with less friction, which in turn reduces the amount of heat generated. In contrast, conventional grinding wheels often generate more heat because their abrasives tend to be harder and more aggressive, resulting in increased friction.

By maintaining a steady and even abrasive action, they help prevent localized heat spots that could cause surface damage. This feature is especially beneficial when working on delicate or precision components, where even slight temperature changes could cause performance issues or cosmetic defects.

Lower Operating Temperatures for Sensitive Materials

For materials that are sensitive to heat, such as polymers, composites, or some metals, controlling the temperature during grinding and finishing is crucial to avoid degradation. Non-woven fiber Wheels excel in these applications because they generate less heat compared to more traditional abrasive tools. The gentle, less aggressive abrasive action prevents the workpiece from overheating, preserving the material’s integrity.

This makes Non-Woven Fiber Wheels the preferred choice for industries like aerospace, automotive, and electronics, where the precision and quality of materials are paramount. For example, when polishing metal parts in these industries, excessive heat can cause warping or change the metal's hardness. The lower operating temperature ensures that these issues are reduced, maintaining both the aesthetic and functional properties of the workpiece.

Less Heat Impact in Continuous Operations

In long-running or continuous grinding operations, the buildup of heat can accumulate and cause damage over time. Unlike traditional abrasive tools, Non-Woven Fiber Wheels are less prone to causing heat buildup during prolonged use. Their ability to maintain a lower, more consistent temperature makes them ideal for applications that require extended periods of grinding or finishing.

This characteristic is particularly useful in industries where mass production is common, and workers must grind or polish large quantities of parts without having to pause frequently to cool the workpieces. The reduced heat impact of Non-Woven Fiber Wheels ensures that production can proceed smoothly and efficiently, without the risk of damaging the workpieces due to heat exposure.

The Heat Management Benefits

Compared to traditional abrasive tools, Non-Woven Fiber Wheels offer significant advantages in reducing heat buildup and thermal damage during grinding, polishing, and finishing processes. Their open structure allows for better airflow, which facilitates heat dissipation, while their consistent abrasive action reduces friction and heat generation. These features make it especially useful for working with heat-sensitive materials and in continuous operations. By choosing a Non-Woven Fiber Wheel for applications that require precise heat management, industries can ensure better quality finishes, longer tool life, and improved material integrity.

The Twisted Wire Bowl Wire Brush is a powerful and durable cleaning and finishing tool designed for heavy-duty industria...

See Details

The Bowl Wire Brush is a versatile and durable cleaning tool designed for various surface preparation tasks, including r...

See Details

A CNC bending machine is a high-precision piece of equipment designed to bend metal sheets and plates with high accuracy...

See Details

The Precision High-Speed Pneumatic Punch Press is designed to deliver reliable performance for a wide range of industria...

See Details+86-18867586928

Contact Us