Cat:Stamping Die

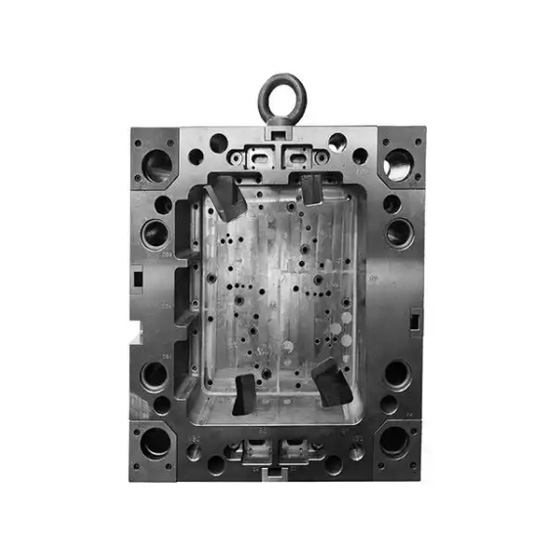

Metal injection molds are a widely used manufacturing process that produces parts by injecting molten material into a mo...

See DetailsIn the world of brush production, selecting the appropriate machinery is crucial for ensuring operational efficiency, product quality, and cost-effectiveness. With advances in industrial automation, manufacturers are often faced with the decision between using fully automated Brush Making Machinery or semi-automatic systems. Each type of equipment has distinct advantages and limitations, depending on production scale, labor availability, and specific application needs. This article explores the key differences between these two types of machinery, helping manufacturers make informed choices.

A major advantage of fully automated Brush Making Machinery is its high productivity. These machines can operate continuously with minimal human intervention, enabling manufacturers to produce large volumes of brushes in a consistent and repeatable manner. Automated systems are typically equipped with servo motors, precision controls, and intelligent programming interfaces that allow for fast cycle times and complex brush designs without slowing down production.

In contrast, semi-automatic brush-making machines require human assistance for certain operations, such as material loading, positioning, or part transfer between stages. While this setup can still yield reasonable output, it is generally slower than fully automated alternatives. For small to medium-sized enterprises or custom brush producers, however, the moderate output of semi-automatic systems may be adequate and more financially practical.

Another strength of automated Brush Making Machinery lies in consistency and precision. The computer-controlled processes reduce variations in brush shape, bristle density, and alignment, which enhances the overall product quality. This level of precision is especially important in industries like personal care, electronics, and medical devices, where strict tolerances are required.

Semi-automatic machines, by involving manual steps, may result in slight variations between batches or even within a single production run. While experienced operators can maintain acceptable quality, the process is inherently more susceptible to human error. This makes semi-automatic systems less suitable for industries that demand tight specifications or where uniformity is critical.

From a labor standpoint, automated brush-making equipment significantly reduces the reliance on manual labor. Once programmed, these machines can run with minimal supervision, allowing operators to focus on other tasks. This can help reduce long-term labor costs and mitigate the impact of labor shortages or high turnover.

On the other hand, semi-automatic machines require skilled workers to manage operations, which means labor costs remain a substantial factor. However, this also provides more flexibility for custom orders or small production runs, where operator adjustments can quickly be made without the need for reprogramming the entire system.

In terms of investment and maintenance, fully automated machinery involves a higher upfront cost and more complex maintenance procedures. The integration of sensors, robotics, and software systems requires both initial capital and skilled technical support. Semi-automatic equipment is generally simpler in design, easier to maintain, and cheaper to acquire, making it a more accessible option for businesses with budget constraints or those just entering the brush manufacturing industry.

Adaptability is another key consideration. Semi-automatic systems often allow for quicker product changeovers, as operators can manually adjust settings for different brush types or sizes. While modern automated machinery can also handle product variation through programmable settings, switching between designs may require more time and technical knowledge.

In conclusion, fully automated Brush Making Machinery offers efficiency, consistency, and labor savings, making it ideal for high-volume manufacturers prioritizing quality and scalability. Semi-automatic systems, while less efficient, provide flexibility, lower investment barriers, and easier adaptation for smaller operations. Ultimately, choice depends on a company’s production goals, available resources, and long-term growth strategy.

Metal injection molds are a widely used manufacturing process that produces parts by injecting molten material into a mo...

See Details

The pen type wire brush is a versatile tool designed for cleaning, deburring, polishing, and surface preparation. Compac...

See Details

The pen-shaped twisted wire brush is a versatile, compact tool designed for cleaning, polishing, and surface preparation...

See Details

A Precision CNC Bending Machine is a state-of-the-art piece of equipment designed for accurate and efficient metal sheet...

See Details+86-18867586928

Contact Us