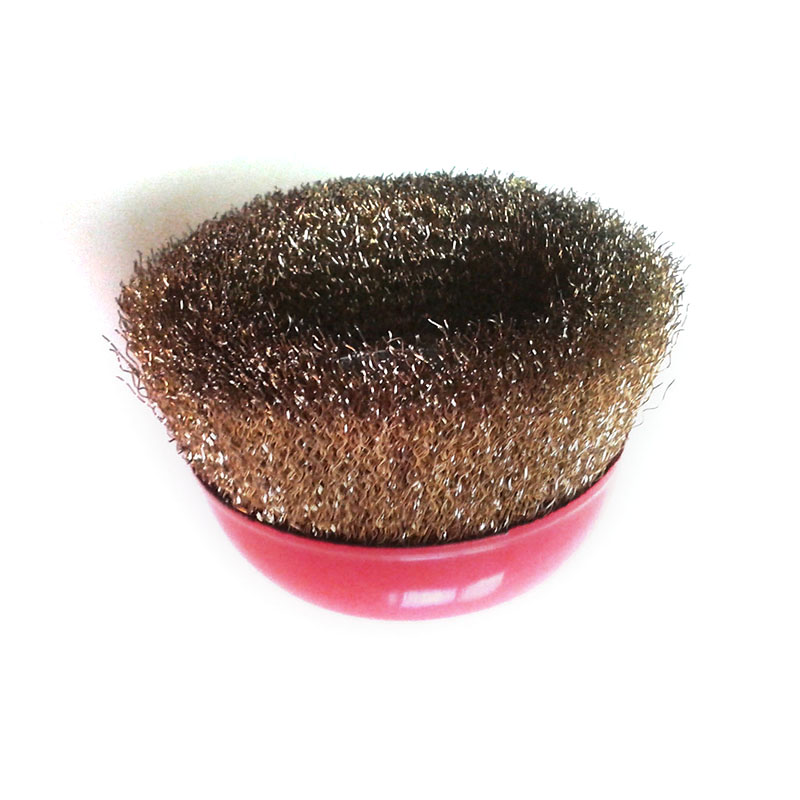

Cat:Wire Wheel Brush

The Twisted Wire Bowl Wire Brush is a powerful and durable cleaning and finishing tool designed for heavy-duty industria...

See DetailsCoarse Grit for Heavy Material Removal

Coarse grit Non-Woven Fiber Wheel, typically in the range of 24 to 60 grit, is ideal for aggressive material removal. These wheels are designed to handle tougher surfaces and are commonly used in applications where rapid material removal is necessary, such as deburring, grinding welds, and removing rust or paint from metal surfaces. The larger abrasive particles in these wheels enable them to quickly remove more material, making them effective for applications that require significant surface preparation or smoothing of rough edges.

Coarse grits are especially useful when working with hard metals or materials that have significant surface imperfections. They can also be employed in industries like construction, automotive, and aerospace, where strong abrasives are required for heavy-duty applications. However, the finish produced by coarse grit wheels tends to be rough, and additional finishing steps may be required for a smooth surface.

Medium Grit for General Surface Finishing

Medium grit Non-Woven Fiber Wheels, typically ranging from 80 to 120 grit, are the go-to choice for general surface finishing and cleaning tasks. These wheels offer a balanced approach between material removal and surface smoothness, making them suitable for a wide variety of applications, including cleaning metal parts, deburring edges, and achieving a satin finish on softer materials like aluminum or brass.

Medium grit wheels are effective for light to moderate polishing, blending weld seams, and removing light oxidation from surfaces. The finish they provide is smoother than what coarse grit wheels offer, making them ideal for preparing surfaces for further finishing processes like coating or painting. These wheels are commonly used in industries such as automotive repair, appliance manufacturing, and metalworking.

Fine Grit for Polishing and Final Finishes

Fine grit Non-Woven Fiber Wheels, typically ranging from 150 to 320 grit, are used for polishing and providing the final finish on materials. These wheels are ideal for achieving a smooth, glossy, or matte finish on softer materials like wood, plastic, or stainless steel. Fine grits are designed to refine surfaces, removing any minor imperfections or surface scratches that may have been left by coarser wheels.

In addition to polishing, fine grit wheels are also used for cleaning delicate surfaces, such as in the electronics or jewelry industries. They can also be used to achieve satin finishes or add a uniform texture to the surface of a workpiece. Fine grit Non-Woven Fiber Wheels are often the choice for applications requiring a high level of surface detail and precision, where even the imperfections need to be removed.

Extra Fine Grit for Ultra-Smooth Finishing

For those requiring an ultra-smooth finish, extra fine grit Non-Woven Fiber Wheels, ranging from 400 to 600 grit or higher. These wheels are used for ultra-fine polishing and for applications where a mirror-like finish is required. They are often employed in industries like automotive detailing, aerospace, and high-end manufacturing, where the final appearance of the surface is critical.

Extra fine grit wheels are ideal for delicate tasks that demand the removal of fine surface scratches or imperfections. They are also used in finishing processes where the workpiece needs to be smooth to the touch, without any visible texture or marks. This grit is often the final step before a protective coating or plating is applied to ensure a possible surface for adhesion.

Choosing the Right Grit for Suitable Performance

The grit size of a Non-Woven Fiber Wheel directly impacts its performance and the quality of the finish it produces. Coarse grits are ideal for aggressive material removal, while medium grits are suited for general surface finishing. Fine and extra fine grits offer more delicate finishing and polishing tasks, resulting in smoother, more refined surfaces. By choosing the correct grit size for each specific task, operators can optimize both efficiency and quality, ensuring that their workpieces meet the required specifications.

The Twisted Wire Bowl Wire Brush is a powerful and durable cleaning and finishing tool designed for heavy-duty industria...

See Details

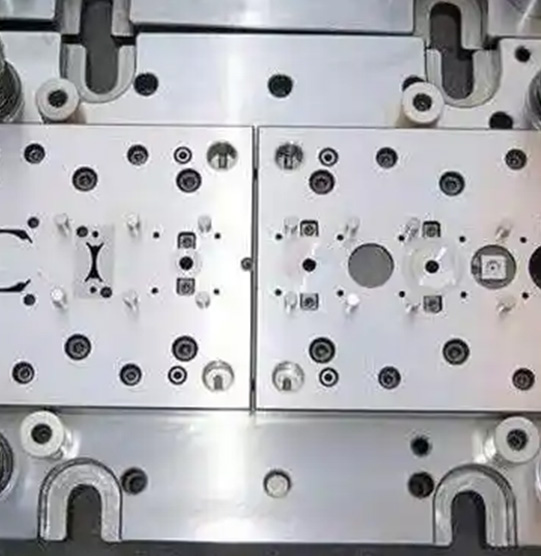

A single-strike die is a specialized tool used in the manufacturing industry for single-impact stamping of metal molds. ...

See Details

The Bowl Wire Brush is a versatile and durable cleaning tool designed for various surface preparation tasks, including r...

See Details

The Precision High-Speed Pneumatic Punch Press is designed to deliver reliable performance for a wide range of industria...

See Details+86-18867586928

Contact Us