Cat:Non-Woven Fiber Wheel Production Machine

A nonwoven bonding machine is a highly specialized piece of equipment designed to apply adhesive and sand to nonwoven fa...

See DetailsThe durability of automation machinery and equipment is a critical factor that influences the overall performance and efficiency of manufacturing operations. As industries continue to embrace automation to enhance production capabilities, the longevity and reliability of these automated systems are key considerations for businesses. In a world where operational downtime can cause significant financial losses, ensuring that automation machinery and equipment remain functional and efficient for extended periods is crucial. This article explores the factors that contribute to the durability of these systems, as well as the challenges and strategies for maximizing their lifespan.

Several factors determine the durability of automation machinery and equipment. The quality of materials used in the construction of the machines is perhaps the important factor. High-quality materials, such as robust metals and advanced alloys, ensure that machines can withstand harsh operating conditions, including extreme temperatures, heavy workloads, and frequent movement. The engineering and design of automation systems also impact their durability. Machines that are designed for easy maintenance and with a modular structure tend to last longer, as they can be easily repaired or upgraded without the need for a complete overhaul.

Another important factor is the environment in which the machinery operates. Automation equipment in industries such as mining, construction, or food processing faces more extreme conditions than machinery used in office or light industrial settings. Dust, moisture, chemicals, and temperature fluctuations can all negatively affect the durability of machines. Therefore, automation systems that are built to operate in such environments need to be specially designed with protective features to shield them from these adverse conditions.

The maintenance and servicing of automation machinery and equipment play a significant role in extending their lifespan. Regular inspections and timely repairs can prevent minor issues from becoming major problems. Predictive maintenance, driven by IoT-enabled systems, allows for real-time monitoring of machinery performance. This technology can detect early signs of wear and tear, such as overheating or unusual vibrations, enabling maintenance teams to address issues before they cause equipment failure.

The use of preventative maintenance schedules is also a key strategy for ensuring the durability of automation systems. This proactive approach includes replacing worn-out components, lubricating moving parts, and cleaning machinery to prevent the buildup of dust and debris. Many manufacturers also provide training for operators to ensure they follow practices for machine use, which can significantly reduce the likelihood of damage and increase the machine's overall lifespan.

Despite the advancements in automation technology, there are still several challenges that impact the durability of automation machinery and equipment. One of the primary challenges is the high cost of maintenance for complex automated systems. While automation can reduce operational costs over time, the maintenance of sophisticated machinery can be expensive, especially if specialized parts or technicians are required for repairs.

The durability of automation machinery and equipment is a fundamental aspect of ensuring continuous and efficient production in modern industries. By considering factors such as the quality of materials, environmental conditions, and regular maintenance, businesses can improve the lifespan of their automated systems. As technology continues to evolve, automation systems will become even more durable and reliable, offering businesses greater efficiency and reduced costs. However, the challenges associated with maintenance, human error, and obsolescence must still be addressed to ensure that automation machinery continues to provide value for years to come.

A nonwoven bonding machine is a highly specialized piece of equipment designed to apply adhesive and sand to nonwoven fa...

See Details

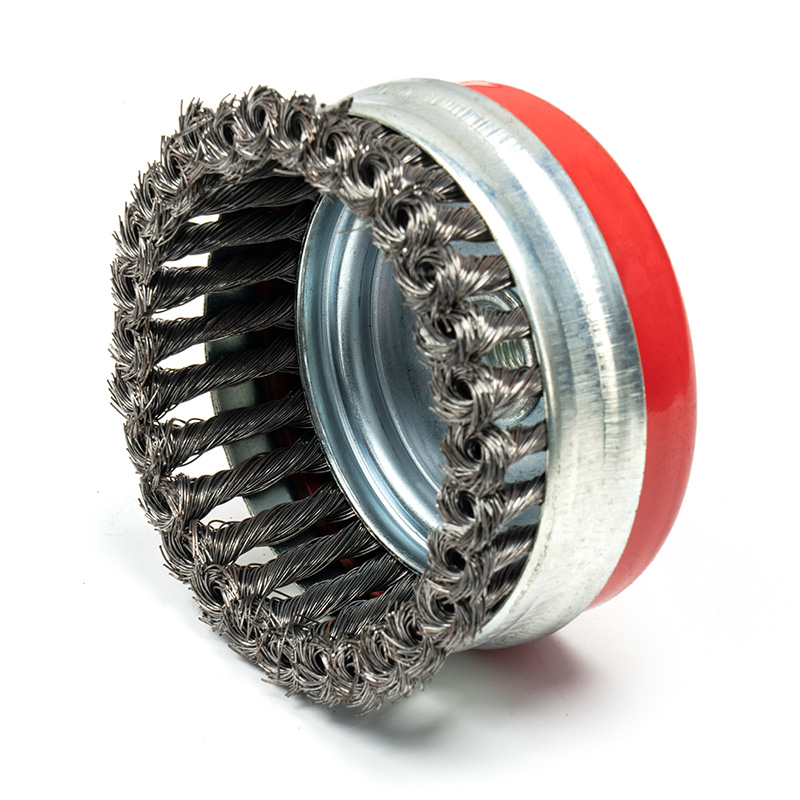

Twisted Wire Cup Wire Brush: Robust Cleaning and Surface Preparation Tool The twisted wire cup wire brush is a versatile...

See Details

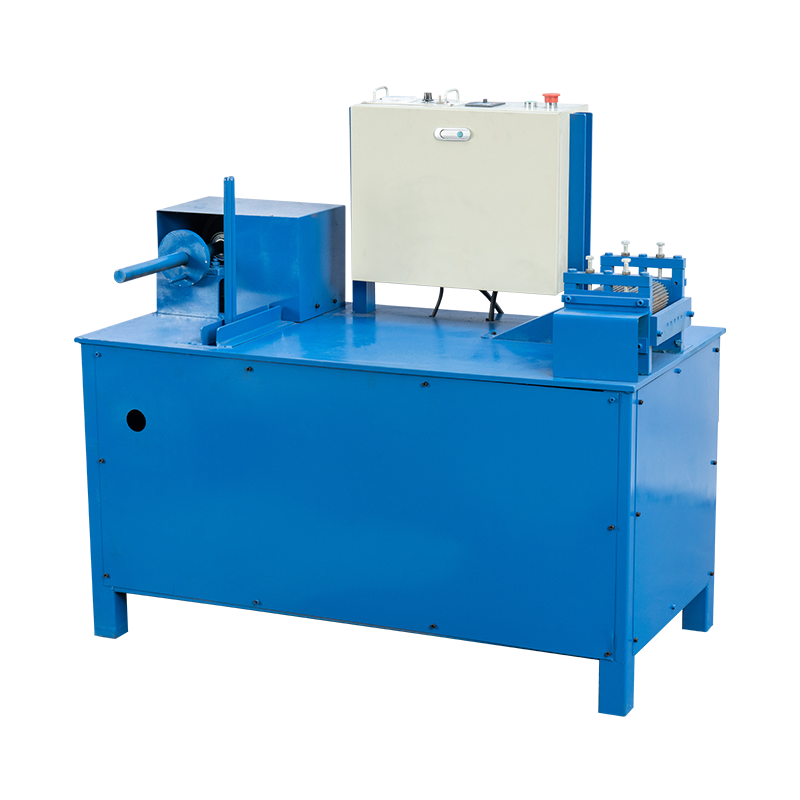

The Automatic Twist Steel Wire Cutting Machine is a revolutionary piece of equipment designed to address the specific ne...

See Details

High-Performance Pneumatic PunchThe High-Performance Pneumatic Punch is a precision-engineered tool designed for high-sp...

See Details+86-18867586928

Contact Us