Cat:Wire Wheel Brush

Made from twisted wire filaments, this brush is used extensively in industrial and maintenance applications for tasks th...

See DetailsIndustrial production environments often present harsh conditions such as high temperatures, elevated humidity, and excessive dust. These factors can significantly affect the performance and longevity of machinery if not properly addressed. Automation Machinery And Equipment must be designed with robust engineering solutions to maintain operational efficiency and reliability under such conditions. Understanding how these machines adapt to environmental stressors is crucial for manufacturers seeking uninterrupted production and maintenance requirements.

High-temperature environments pose challenges to both mechanical and electronic components. Thermal expansion can affect precision, while excessive heat may degrade lubricants, belts, and electronic circuits. To adapt, automation machinery often incorporates heat-resistant materials, high-temperature lubricants, and cooling systems such as fans, heat exchangers, or liquid cooling loops. Control panels and sensitive electronics may be enclosed in insulated or ventilated housings to prevent overheating. Machines designed for elevated temperatures maintain operational stability while reducing downtime caused by thermal stress.

High humidity can cause condensation, corrosion, and electrical short circuits, all of which compromise machinery performance. To address this, automation equipment is often coated with anti-corrosive materials or treated with protective finishes. Electrical enclosures may be rated for moisture protection (e.g., IP65 or higher), and seals or gaskets are used to prevent water ingress. In addition, some machines incorporate humidity sensors and automated shutdown features to prevent damage during extreme conditions. These strategies ensure that automation systems maintain reliability in environments such as food processing, chemical plants, or tropical regions.

Dusty environments, common in metalworking, woodworking, or mining operations, can interfere with mechanical movement and clog sensors or electronic components. Automation machinery is equipped with protective covers, sealed enclosures, and filtration systems to decrease dust penetration. Moving parts may use self-lubricating components or dust-resistant bearings to sustain smooth operation. Maintenance routines often include regular cleaning and filter replacement to ensure that dust accumulation does not hinder machine performance. By addressing dust intrusion proactively, equipment can operate continuously without unexpected failures.

The adaptability of automation machinery is also dependent on material choice and structural engineering. Corrosion-resistant metals, reinforced plastics, and high-quality coatings extend the life of components in challenging conditions. Structural designs often incorporate modularity and easy-access panels, allowing maintenance without disassembling critical systems. These design considerations ensure that the equipment remains both durable and serviceable even in extreme production environments.

Reliable automation machinery is rigorously tested under simulated high-temperature, high-humidity, and dusty conditions to validate performance. Industry standards such as IEC, ISO, and NEMA guide manufacturers in designing equipment that meets environmental protection requirements. Proper testing ensures that automation systems perform predictably, reducing downtime, production loss, and maintenance costs. Choosing equipment that has been certified for harsh environments provides assurance for long-term operational reliability.

Automation Machinery and Equipment demonstrates strong adaptability in high-temperature, high-humidity, and high-dust environments through careful material selection, protective design features, and rigorous testing. Cooling systems, anti-corrosion measures, dust-resistant structures, and moisture protection all contribute to maintaining operational efficiency and extending equipment lifespan. By understanding these adaptations and selecting machinery rated for harsh conditions, manufacturers can achieve consistent performance, reduce maintenance interventions, and optimize productivity across demanding industrial settings.

Made from twisted wire filaments, this brush is used extensively in industrial and maintenance applications for tasks th...

See Details

The Twisted Wire Bowl Wire Brush is a powerful and durable cleaning and finishing tool designed for heavy-duty industria...

See Details

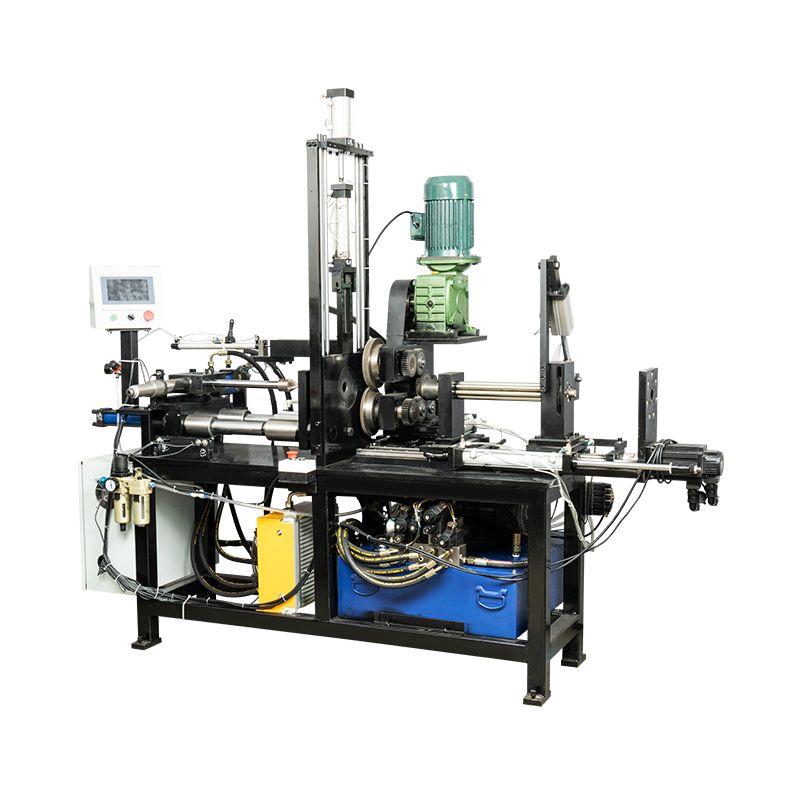

The Precision CNC Hydraulic Press is a versatile and efficient tool designed for high precision metal forming and fabric...

See Details

High-Performance Pneumatic PunchThe High-Performance Pneumatic Punch is a precision-engineered tool designed for high-sp...

See Details+86-18867586928

Contact Us