Cat:Wire Wheel Brush

The Twisted Wire Bowl Wire Brush is a powerful and durable cleaning and finishing tool designed for heavy-duty industria...

See DetailsNon-Woven Fiber Wheels are widely used in various industrial applications such as polishing, grinding, and finishing. Their ability to deliver consistent and smooth results on diverse materials like metal, plastic, and wood has made them essential tools in many industries. However, to achieve results and prolong the life of the Non-Woven Fiber Wheel, it is crucial to control two primary factors during operation: pressure and rotational speed. These elements directly influence the wheel's effectiveness and durability.

Understanding the Impact of Pressure

The pressure applied during the operation of a Non-Woven Fiber Wheel plays a significant role in the grinding or polishing process. Applying too much pressure can cause the fibers to break down faster, causing premature wear and reduced wheel life. It can also create uneven finishes and potentially damage the surface being worked on. On the other hand, too little pressure may result in ineffective material removal, causing an incomplete finish or longer processing times.

To achieve suitable performance, it is recommended to apply moderate, consistent pressure that allows the Non-Woven Fiber Wheel to make effective contact with the material without forcing it into the workpiece. In many cases, manufacturers provide guidelines on the appropriate pressure for specific applications. It is also important to ensure that the wheel is not pushed into the workpiece, as this can cause heat buildup, which may affect the finish quality.

Controlling Rotational Speed for Consistency

The rotational speed at which the Non-Woven Fiber Wheel operates is another critical factor that impacts its performance. A wheel spinning at high speeds can generate excess heat and cause the abrasive fibers to degrade more quickly. Conversely, using a low speed may result in insufficient material removal, longer processing times, and lower efficiency.

To strike the right balance, it is important to adjust the speed according to the material being worked on and the type of finish required. For instance, when working with harder materials or requiring more aggressive material removal, a higher speed may be needed. In contrast, for delicate surfaces or fine finishing tasks, lower speeds should be employed to reduce the risk of damage and to achieve a smoother finish.

Matching Pressure and Speed with Material Type

Different materials require different combinations of pressure and speed. For example, when using a Non-Woven Fiber Wheel on metals, higher speeds may be required to achieve a polished or satin finish, but excessive pressure should still be avoided. On softer materials like plastic or wood, lower speeds and gentler pressure can prevent surface marring and excessive wear of the wheel.

A good rule of thumb is to always start with the manufacturer’s recommendations for both pressure and speed settings, and then adjust based on the specific material and desired finish. Fine-tuning these factors ensures that the Non-Woven Fiber Wheel delivers the results without unnecessary wear or inefficiency.

Practical Tips for Optimal Control

To ensure consistent pressure and speed, operators should use adjustable machines that allow fine control over these factors. Whether using a handheld tool or a machine, it’s important to maintain a steady hand to avoid uneven pressure distribution across the wheel’s surface. Additionally, periodically checking the condition of the wheel and adjusting the speed accordingly can prevent overheating and uneven wear.

In some cases, it may be beneficial to perform test runs on scrap materials to fine-tune pressure and speed settings before beginning on the actual workpiece. This helps avoid potential issues such as excessive heat buildup, surface damage, or inefficient material removal.

Maintaining Suitable Performance of Non-Woven Fiber Wheels

Controlling pressure and rotational speed during its use is essential for achieving a finish and prolonging the life of the wheel. By applying moderate pressure and adjusting the speed according to the material being worked on, users can ensure that the wheel performs, delivering consistent and high-quality results. Proper control of these factors not only improves efficiency but also prevents unnecessary damage to both the workpiece and the wheel itself.

The Twisted Wire Bowl Wire Brush is a powerful and durable cleaning and finishing tool designed for heavy-duty industria...

See Details

It features curved wire bristles that provide superior flexibility and uniform contact with the surface, ensuring effici...

See Details

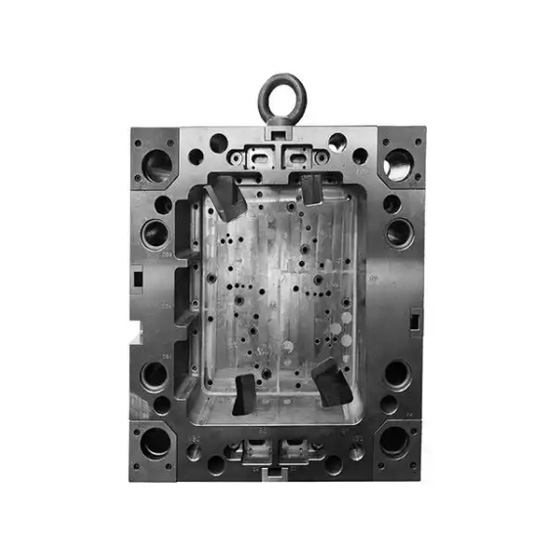

Metal injection molds are a widely used manufacturing process that produces parts by injecting molten material into a mo...

See Details

The Durable Non-Woven Fiber Wheel is an advanced tool designed for a variety of industrial surface finishing tasks. Craf...

See Details+86-18867586928

Contact Us