Cat:Wire Wheel Brush

Featuring a bowl-shaped configuration and twisted wire bristles, this brush is suitable for industrial and automotive ap...

See DetailsNon-Woven Fiber Wheels are versatile abrasive tools widely used in metalworking, woodworking, and finishing industries. One of their key advantages is the availability of different hardness levels and fiber densities, which allows operators to select the appropriate wheel for specific tasks. Understanding how these variations affect performance, material removal, and surface finish is essential for achieving suitable results in any application.

Understanding Hardness in Fiber Wheels

The hardness of a Non-Woven Fiber Wheel determines how aggressively it removes material from the workpiece. Softer wheels conform more easily to irregular surfaces, providing gentle abrasion suitable for polishing, finishing, or blending welds. Harder wheels offer more aggressive material removal and are ideal for deburring, surface preparation, and the removal of oxidation or coatings. Choosing the correct hardness ensures that the workpiece is treated without over-cutting or damaging the surface, particularly when working with delicate materials such as aluminum or soft metals.

Influence of Fiber Density

Fiber density affects the rigidity and durability of the wheel. Low-density wheels are more flexible, allowing the wheel to adapt to complex shapes and contours, making them suitable for curved or irregular surfaces. High-density wheels, in contrast, provide greater stability and consistency for flat surfaces and heavy-duty tasks. Dense wheels also tend to maintain their shape longer under repeated use, offering more predictable performance in high-volume operations. Balancing fiber density with wheel hardness allows operators to customize the abrasive action for specific processing needs.

Applications for Softer, Low-Density Wheels

Softer, low-density Non-Woven Fiber Wheels excel in applications requiring precision and surface quality rather than rapid material removal. These wheels are ideal for final polishing, blending weld seams, or removing light oxidation and corrosion without leaving scratches. They are also suitable for finishing delicate materials like brass, copper, or plastic composites, where aggressive abrasion could compromise the integrity or aesthetics of the workpiece. The flexibility of low-density wheels ensures uniform contact across curves, edges, and complex geometries.

Applications for Harder, High-Density Wheels

Harder, high-density wheels are preferred for tasks demanding efficient material removal and durability. These wheels are effective in deburring machined parts, removing rust, paint, or coatings, and preparing surfaces for welding or coating applications. The combination of hardness and density allows the wheel to maintain consistent contact, resist deformation, and deliver rapid results on flat or heavy-duty surfaces. These wheels are particularly beneficial in industrial environments where speed, consistency, and long service life are critical.

Selecting the Right Combination for Specific Needs

Choosing the proper Non-Woven Fiber Wheel involves considering both hardness and density in relation to the material and task requirements. Softer, flexible wheels provide gentle finishing and adaptability, while harder, denser wheels deliver aggressive material removal and durability. By evaluating the workpiece material, surface geometry, and desired finish, operators can select a suitable wheel to balance efficiency, quality, and longevity.

Matching Fiber Wheel Properties to Tasks

Non-Woven Fiber Wheels offer a wide range of hardness and density options to meet diverse industrial needs. Understanding these characteristics allows operators to select the appropriate wheel for polishing, deburring, surface preparation, or finishing. Softer, low-density wheels are ideal for precision and delicate surfaces, whereas harder, high-density wheels excel in heavy-duty material removal. By matching wheel properties to specific applications, users can optimize performance, maintain surface quality, and extend tool life, ensuring consistent, high-quality results in every operation.

Featuring a bowl-shaped configuration and twisted wire bristles, this brush is suitable for industrial and automotive ap...

See Details

The Automatic Wire Cutting Machine is designed to streamline the process of wire-cutting, particularly in industries whe...

See Details

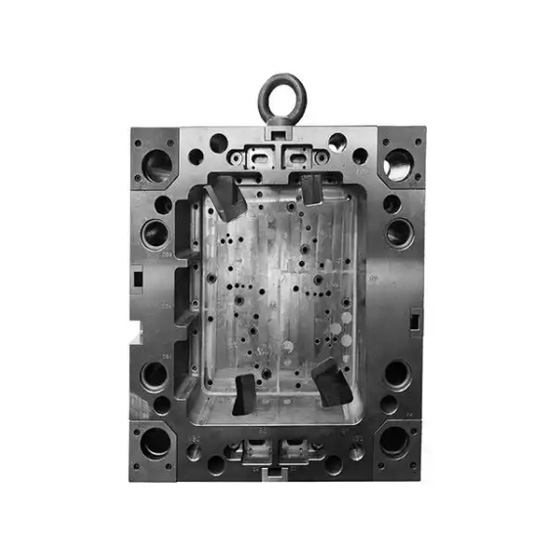

Metal injection molds are a widely used manufacturing process that produces parts by injecting molten material into a mo...

See Details

The CNC high precision bending machine is designed for bending metal sheets, such as steel, aluminum, and stainless stee...

See Details+86-18867586928

Contact Us