Cat:Brush Making Machine

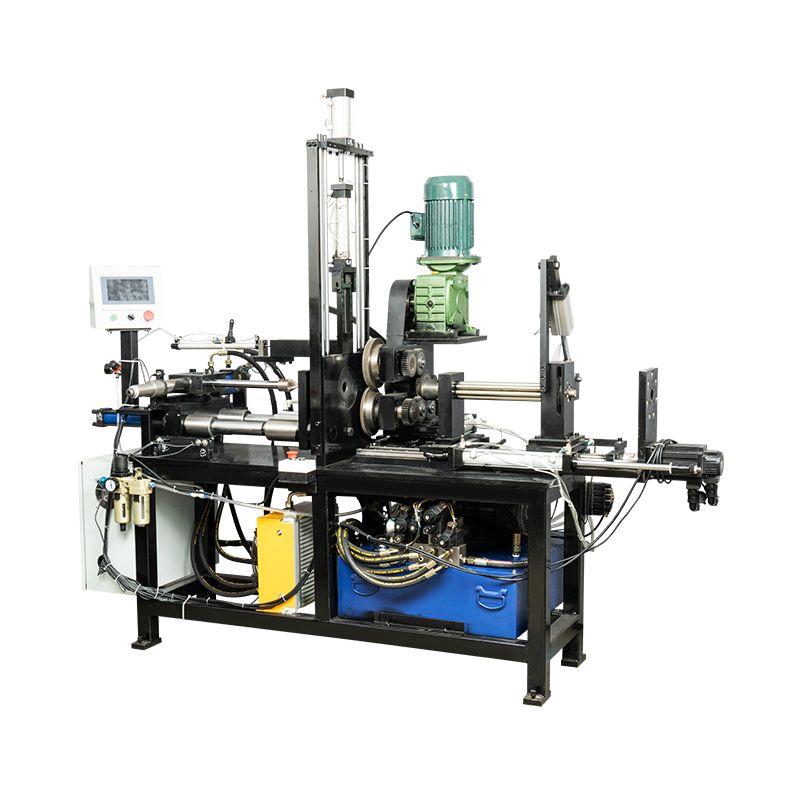

The Curved Brush Chip Cleaning Machine is engineered to solve common challenges in chip manufacturing, where cleanliness...

See DetailsDurability and lifespan are key considerations when selecting abrasive tools for metalworking, woodworking, or finishing operations. Non-woven fiber Wheels are widely valued for their controlled abrasion, adaptability, and consistent performance. However, understanding the factors that influence their wear rate and effective service life is essential for planning maintenance schedules, ensuring efficiency, and reducing replacement costs in industrial and workshop settings.

Material Composition and Its Impact on Durability

The durability of a Non-Woven Fiber Wheel is largely determined by its composition. These wheels consist of interlaced synthetic fibers impregnated with abrasive grains, forming a resilient and porous structure. The type of fibers, the bonding method, and the abrasive material itself influence how well the wheel resists wear during operation. High-quality fiber wheels with dense, evenly distributed abrasive grains tend to maintain performance over extended use, providing consistent material removal without rapid degradation of the wheel structure.

Factors Affecting Lifespan

Several operational and environmental factors affect the lifespan of fiber wheels. The hardness of the workpiece material, the applied pressure during grinding, and the rotational speed all influence wear rate. Excessive force or high-speed operation can accelerate fiber breakdown and abrasive grain loss, shortening the effective life of the wheel. Additionally, exposure to moisture, heat buildup, or chemical contaminants can degrade the fibers, further impacting durability. Selecting the appropriate wheel for the material and operational conditions is critical for improving service life.

Typical Lifespan Expectations

While actual service life varies depending on usage, a high-quality Non-Woven Fiber Wheel typically offers hundreds of hours of operational performance under normal conditions. In high-volume industrial applications, operators may experience a gradual decline in material removal efficiency after prolonged use, signaling the need for replacement. Unlike rigid grinding wheels that may fracture or create uneven wear patterns, fiber wheels tend to wear consistently, providing predictable performance until fully consumed. This consistency aids in planning maintenance cycles and reducing unexpected downtime.

Maintenance Practices to Extend Durability

Proper care and handling can significantly enhance the lifespan of fiber wheels. Cleaning the wheel regularly to remove debris and metal particles prevents clogging and maintains consistent abrasive contact. Avoiding excessive pressure and allowing the wheel to work at its suitable speed reduces mechanical stress and heat buildup, preserving the fiber matrix. Storing the wheel in a dry environment and avoiding exposure to harsh chemicals also helps maintain structural integrity. By following these practices, operators can extend the operational life of the wheel and maintain efficiency.

Economic and Operational Advantages

The long lifespan and predictable wear characteristics of Non-Woven Fiber Wheels provide economic and operational benefits. Reduced frequency of replacements lowers consumable costs, while consistent performance ensures uniform finishing quality and reduces rework. For industrial processes where downtime and product quality are critical, investing in durable fiber wheels translates into improved productivity, cost savings, and enhanced safety by reducing the need for frequent handling and tool changes.

Performance Through Fiber Wheels

Non-woven fiber Wheels offer durability and a reliable lifespan, making them suitable for a wide range of finishing, polishing, and deburring tasks. Their consistent wear, adaptable fiber structure, and resistance to premature degradation ensure effective performance throughout their service life. By understanding the factors that affect longevity and implementing proper operational practices, users can improve efficiency, reduce costs, and achieve high-quality results with disruption. Selecting the right fiber wheel for the application and maintaining it properly ensures long-term productivity and value in demanding industrial environments.

The Curved Brush Chip Cleaning Machine is engineered to solve common challenges in chip manufacturing, where cleanliness...

See Details

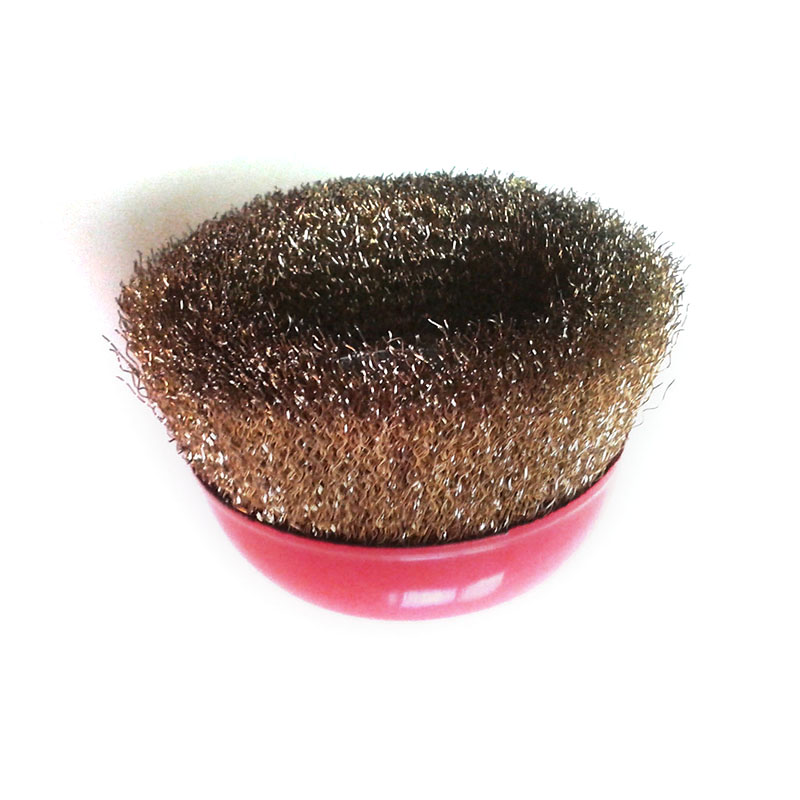

The Bowl Wire Brush is a versatile and durable cleaning tool designed for various surface preparation tasks, including r...

See Details

The High Temperature Resistant Non-Woven Fiber Wheel is a specialized industrial tool designed for precision surface pre...

See Details

A Precision CNC Bending Machine is a state-of-the-art piece of equipment designed for accurate and efficient metal sheet...

See Details+86-18867586928

Contact Us