Cat:Wire Wheel Brush

Its disc-shaped design, with tightly twisted wire bristles, provides uniform contact with the surface, making it ideal f...

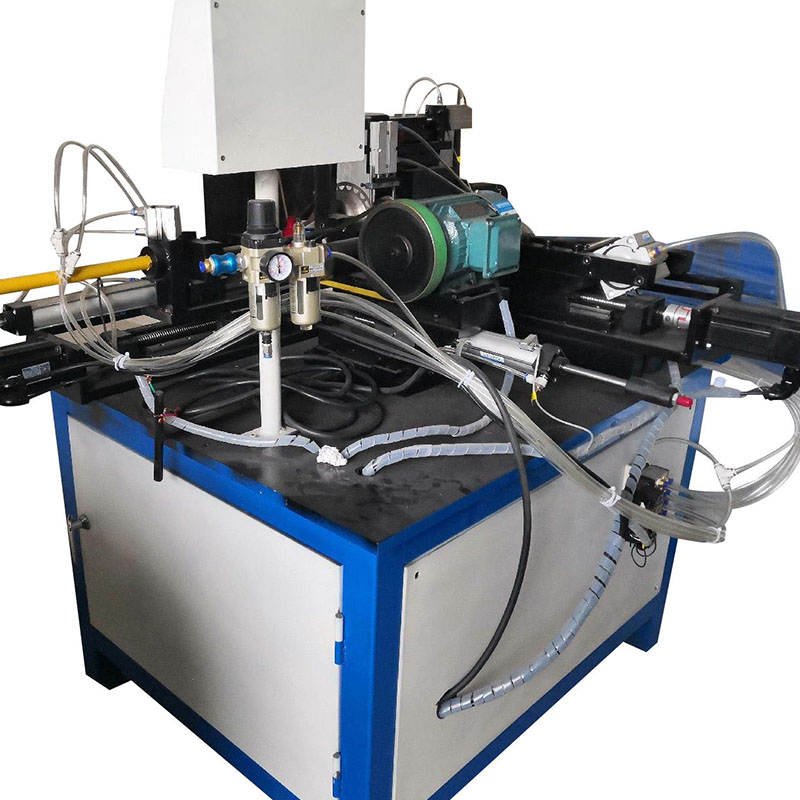

See DetailsNon-Woven Fiber Wheel Production Equipment plays a pivotal role in manufacturing high-quality abrasive and polishing wheels. Two of the critical parameters that determine the performance and longevity of these wheels are hardness and density. Proper control of these characteristics ensures consistent grinding, polishing efficiency, and safety during use. Understanding how production equipment influences these factors is essential for manufacturers aiming to meet diverse application requirements and maintain competitive quality standards.

The hardness of a non-woven fiber wheel is primarily determined by the bonding materials, fiber composition, and applied pressure during formation.

Density control is essential to ensure that the wheel maintains uniform contact with the workpiece and provides predictable wear rates.

Advanced Non-Woven Fiber Wheel Production Equipment is equipped with several features that enable precise control over hardness and density.

Properly controlled hardness and density directly affect wheel performance in various applications.

Despite technological advancements, challenges remain in controlling wheel properties. Variations in fiber quality, resin viscosity, and environmental conditions can impact consistency. Operators must regularly calibrate equipment, monitor material batches, and implement quality checks to reduce deviations. Automated systems with real-time feedback significantly reduce human error and enhance reproducibility.

Non-Woven Fiber Wheel Production Equipment achieves control over wheel hardness and density through a combination of fiber management, adjustable pressing, temperature regulation, and monitoring systems. These factors collectively ensure that the wheels meet performance requirements, maintain safety standards, and offer versatility for diverse industrial applications. By carefully managing these parameters, manufacturers can produce high-quality wheels with predictable wear, consistent efficiency, and reliable durability, solidifying their position in a competitive market.

Its disc-shaped design, with tightly twisted wire bristles, provides uniform contact with the surface, making it ideal f...

See Details

The Full-Automatic Wire Twist Pen Brush Machine represents a significant leap in efficiency and precision for manufactur...

See Details

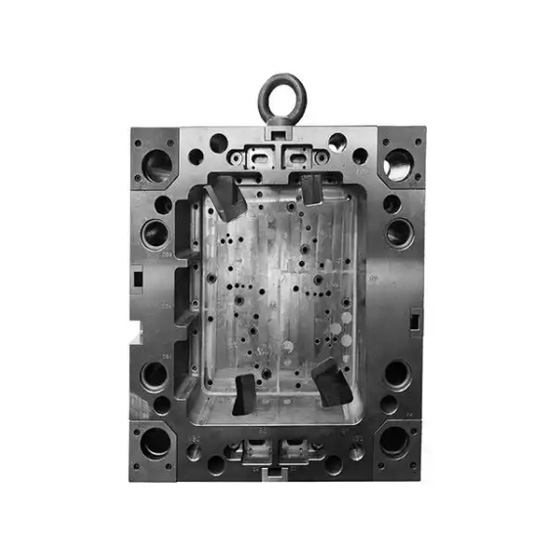

Metal injection molds are a widely used manufacturing process that produces parts by injecting molten material into a mo...

See Details

High-Frequency Curved Wire Brush Segment MachineThe High-Frequency Curved Wire Brush Segment Machine is a specialized to...

See Details+86-18867586928

Contact Us