Cat:Stamping Die

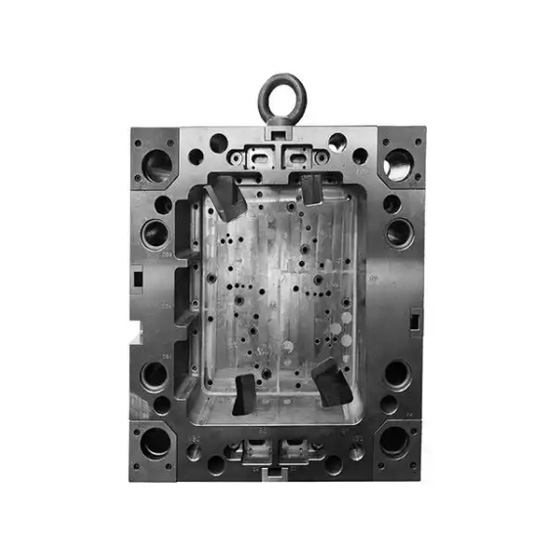

Metal injection molds are a widely used manufacturing process that produces parts by injecting molten material into a mo...

See DetailsMaterial Composition Determines Rust Resistance

The corrosion resistance of a Wire Wheel Brush is largely dependent on the materials used in its construction. Common brush wires include carbon steel, stainless steel, and brass. Among these, carbon steel is susceptible to rust, particularly when stored or operated in humid or wet environments. In contrast, stainless steel wires offer high resistance to corrosion due to the chromium content that forms a protective oxide layer. Brass wire, being non-ferrous, also resists rust effectively, although it is less durable in heavy-duty applications. Thus, the wire material selection plays a critical role in the brush’s longevity and anti-rust properties.

Environmental Exposure and Rust Formation

Operating conditions significantly influence how likely a Wire Wheel Brush is to corrode over time. Brushes used in damp industrial settings, marine environments, or areas with high airborne moisture are at greater risk of rusting if not properly maintained. Carbon steel wire brushes, in particular, can develop surface rust if left exposed after use. If moisture or metal debris remains on the wire surface, it accelerates oxidation. To counter this, it is essential to clean and dry the brush after each use, especially when operating in environments prone to corrosion.

Stainless Steel as a Rust-Resistant Option

For users concerned with the long-term durability and cleanliness of the brush, stainless steel wire variants are the preferred choice. These brushes resist both surface rust and deep corrosion, making them suitable for outdoor use and applications where contamination must be avoided, such as food processing or medical equipment maintenance. Additionally, stainless steel brushes are ideal for working on stainless steel surfaces, as they prevent cross-contamination that can cause rust spots or galvanic corrosion. Their rust resistance, however, typically comes at a higher cost compared to brushes made from carbon steel.

Maintenance Practices That Prevent Brush Rusting

Regardless of the wire material, proper maintenance greatly improves the anti-rust performance of any Wire Wheel Brush. After each use, brushing off accumulated debris and wiping the wires clean reduces the chance of oxidation. In environments with fluctuating humidity or chemical exposure, storing the brush in a sealed, dry container or toolbox helps protect it. Applying a light coat of machine oil to carbon steel brushes can add a temporary protective barrier against moisture, though this practice is not recommended for applications requiring contamination-free performance.

Rust’s Impact on Brush Performance and Safety

If a Wire Wheel Brush begins to corrode, its structural integrity and cleaning effectiveness can deteriorate. Rusty bristles become brittle and may snap off during rotation, increasing the risk of operator injury and reducing the brush’s lifespan. Corrosion also reduces the sharpness and flexibility of the wires, making the brush less effective at removing rust, paint, or surface debris. Regular inspection of the brush, especially if stored for long periods, is important to ensure that rust has not compromised the tool.

Choosing the Right Brush for Rust-Sensitive Applications

In applications where brush cleanliness and anti-rust reliability are critical—such as aerospace, food equipment refurbishment, or electronics—using a rust-resistant Wire Wheel Brush is essential. Stainless steel and brass are ideal for these cases, as they not only resist corrosion themselves but also prevent rust transfer to the workpiece. For general industrial tasks where cost is a bigger concern and brushes are frequently replaced, carbon steel options remain viable with proper care.

Conclusion: Rust Resistance Varies with Material and Maintenance

In summary, the rust resistance of a Wire Wheel Brush is not a fixed trait but rather depends on its material composition, the conditions under which it is used, and how well it is maintained. Stainless steel and brass brushes offer good protection against rust, while carbon steel brushes require more diligent care to avoid corrosion. By understanding these factors and adopting proper storage and cleaning habits, users can extend the life of their brushes and maintain safe, effective surface treatment performance.

Metal injection molds are a widely used manufacturing process that produces parts by injecting molten material into a mo...

See Details

The Automatic Twist Steel Wire Cutting Machine is a revolutionary piece of equipment designed to address the specific ne...

See Details

The Wear-Resistant Non-Woven Fiber Wheel is a highly effective tool designed for a range of surface finishing tasks. Con...

See Details

The CNC high precision shearing machine is designed to cut metal sheets, such as steel and aluminum, with high accuracy ...

See Details+86-18867586928

Contact Us