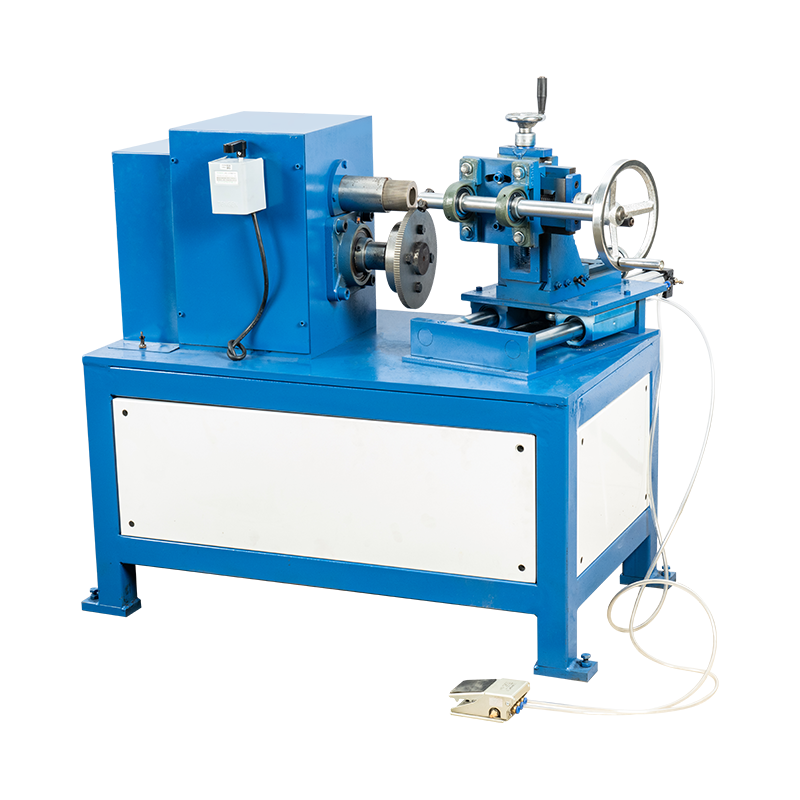

Cat:Brush Making Machine

A common application is in the production of curved wire steel brush bowls, where precision trimming is essential to ens...

See DetailsMaterial Composition and Intended Applications

A Wire Wheel Brush and a nylon brush differ significantly in their material construction, which directly affects both durability and cleaning effectiveness. The wire variant is typically made with carbon steel, stainless steel, or brass wires mounted on a metal hub, designed for aggressive removal of rust, paint, scale, or corrosion. In contrast, a nylon brush is constructed from synthetic polymer bristles, often infused with abrasive grains such as silicon carbide or aluminum oxide, making it more suitable for delicate cleaning, deburring, or polishing where surface integrity must be preserved.

Durability Under Heavy Use Conditions

In terms of pure durability in heavy-duty environments, the Wire Wheel Brush typically outperforms the nylon brush. Its metal construction enables it to maintain structural integrity even under high rotational speeds and substantial pressure. It is well-suited for prolonged use in tasks that involve hard or heavily corroded surfaces. However, this higher durability comes with a trade-off: wire bristles are prone to fatigue over time and may fracture or shed, especially if used improperly. Nylon brushes, while more flexible and less likely to break during use, tend to wear down faster under the same high-friction conditions, particularly when exposed to heat, pressure, or sharp metal edges.

Effectiveness in Surface Cleaning and Finishing

When evaluating cleaning efficiency, the Wire Wheel Brush excels at rapid, aggressive surface preparation. It can effectively strip off thick layers of rust, weld slag, or old coatings in a short amount of time. This makes it ideal for applications in shipyards, metal fabrication, or automotive repair. On the other hand, nylon brushes offer more controlled and uniform material removal. They are often used in precision tasks where maintaining the surface profile is essential, such as in electronics, aluminum components, or soft metals. While not as aggressive as wire brushes, nylon variants are less likely to gouge or scratch the underlying material.

Impact on Workpiece Surface Quality

Another major difference lies in the finish quality each brush produces. A Wire Wheel Brush, due to its rigidity and metal construction, can leave fine scratches or directional marks on soft surfaces. This may require further sanding or polishing, depending on the end-use. Nylon brushes, particularly those embedded with fine abrasives, provide a smoother, more consistent finish. They are commonly used in aesthetic surface treatments, satin finishing, or polishing plastic, wood, and coated metals. The ability of nylon brushes to conform to contours without altering the base material gives them an advantage in fine finishing tasks.

Safety and Operator Comfort Considerations

Safety also plays a role in comparing the two. Wire Wheel Brushes, especially when operating at high speed, pose a risk of flying wire fragments, which can cause injury if proper protective equipment is not used. They also tend to generate more vibration and noise during operation. Nylon brushes, being softer and quieter, present fewer risks of injury from filament breakage and generally offer a more comfortable experience for prolonged manual or automated use.

Cost Efficiency Over Time

From a cost-efficiency standpoint, the decision between the two brushes depends on application needs. Although a Wire Wheel Brush may have a higher upfront cost and shorter replacement intervals due to wire fatigue, its speed and aggressiveness can save time in heavy-duty tasks. Nylon brushes, though they may wear faster in tough environments, can provide longer service in light-duty or precision applications where their gentle action preserves workpiece quality and reduces post-processing needs.

Conclusion: Choosing Based on Task Requirements

In conclusion, the differences in durability and cleaning performance between a Wire Wheel Brush and a nylon brush are rooted in their material design and intended use. For heavy-duty, aggressive cleaning on hard materials, the wire option provides good performance and longer resistance to wear. For controlled, precise, and surface-safe cleaning, especially on delicate or softer materials, nylon brushes offer better finish quality and user safety. Selecting the right tool ultimately depends on balancing the task requirements with desired surface outcomes and long-term efficiency.

A common application is in the production of curved wire steel brush bowls, where precision trimming is essential to ens...

See Details

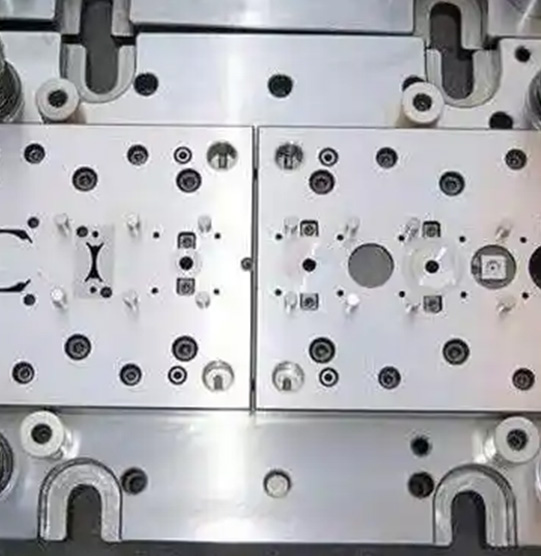

A single-strike die is a specialized tool used in the manufacturing industry for single-impact stamping of metal molds. ...

See Details

The Abrasion-Resistant Non-Woven Fiber Wheel is an advanced abrasive tool designed for a wide range of metalworking appl...

See Details

A CNC bending machine is a high-precision piece of equipment designed to bend metal sheets and plates with high accuracy...

See Details+86-18867586928

Contact Us