Cat:Hydraulic Forming Machine

A metal-forming hydraulic press is a versatile and powerful machine commonly used in a variety of industries to form, sh...

See DetailsNon-Woven Fiber Wheel has become a widely adopted solution in modern abrasive and polishing processes, offering versatility across industries such as metalworking, automotive, and woodworking. With rising energy costs and growing emphasis on sustainable manufacturing, evaluating the energy consumption associated with these wheels is increasingly important. Understanding whether it provides tangible energy-saving advantages helps manufacturers optimize production methods, reduce operational costs, and promote environmentally responsible practices.

The inherent characteristics of non-woven fiber wheels contribute to their energy efficiency. Their lightweight composition reduces rotational inertia, which lowers the energy required for tools to reach and maintain operational speeds. Additionally, the open, porous structure of the fibers facilitates effective contact with the workpiece, reducing friction and improving material removal rates. These material advantages reduce the power demand during use, allowing motors and equipment to operate at lower energy levels while maintaining performance.

The manufacturing process of non-woven fiber wheels further enhances their energy-saving potential. Modern production equipment is designed to handle fibers efficiently, ensuring consistent density and hardness while reducing waste. Precision-controlled compression and curing processes ensure that only the necessary energy is applied to bond the fibers without excessive heating or mechanical pressure. This careful regulation of energy during production results in lower overall energy consumption compared to traditional abrasive wheel manufacturing methods, which often require high-temperature sintering or extended curing cycles.

In practical applications, non-woven fiber wheels demonstrate further energy advantages. Their optimized geometry and uniform structure allow for faster and more efficient cutting, grinding, or polishing. This reduces the operational time needed for a given task, directly lowering energy consumption. The even wear pattern of the wheels also prolongs service life, decreasing the frequency of replacements and the associated energy used in producing additional wheels. As a result, both direct operational energy and indirect energy related to wheel manufacturing are reduced.

When compared to conventional abrasive wheels, non-woven fiber wheels show notable differences in energy usage. Traditional bonded or resin-coated wheels tend to be denser and heavier, requiring more torque to achieve the same rotational speed. Their higher mass and rigidity also contribute to increased friction and energy loss during use. In contrast, non-woven wheels combine lightweight design with efficient material interaction, resulting in lower power requirements and improved energy efficiency throughout the product lifecycle.

The reduced energy consumption associated with non-woven fiber wheels translates into environmental and economic benefits. Lower operational energy decreases electricity demand, while reduced production energy limits carbon emissions and resource utilization. From an economic perspective, energy-efficient wheels lower operational costs for manufacturers and end-users alike. This dual advantage reinforces its value as both a performance-oriented and environmentally conscious solution.

Non-Woven Fiber Wheel demonstrates clear energy-saving potential across production and operational stages. Its lightweight structure, efficient material bonding, and optimized geometry reduce both the energy required during use and the energy consumed in manufacturing. Compared to traditional abrasive wheels, it provides a more sustainable and cost-effective option, supporting efficiency and environmental responsibility. As industries continue to seek methods to reduce energy consumption while maintaining high performance, it offers a practical and effective solution for energy-conscious manufacturing practices.

A metal-forming hydraulic press is a versatile and powerful machine commonly used in a variety of industries to form, sh...

See Details

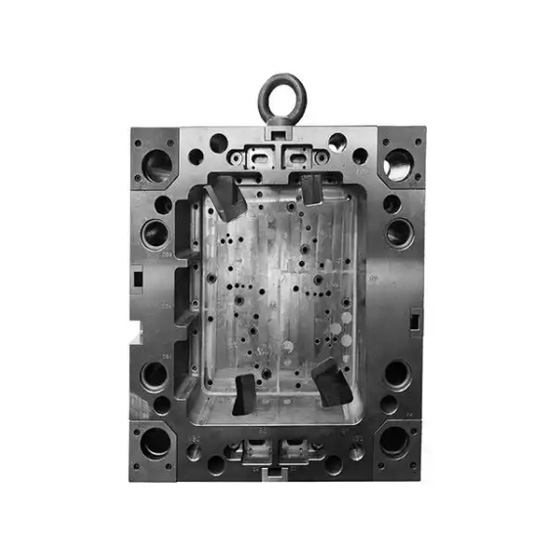

Metal injection molds are a widely used manufacturing process that produces parts by injecting molten material into a mo...

See Details

A polishing wire brush is an essential tool used in a variety of industries for achieving a smooth, polished surface on ...

See Details

High-Performance Pneumatic PunchThe High-Performance Pneumatic Punch is a precision-engineered tool designed for high-sp...

See Details+86-18867586928

Contact Us