Cat:Brush Making Machine

The Full-Automatic Wire Twist Pen Brush Machine represents a significant leap in efficiency and precision for manufactur...

See DetailsNon-Woven Fiber Wheel is widely utilized in abrasive and polishing applications, where consistent performance and reliability are critical. One of the key factors affecting the quality and efficiency of these wheels is the uniformity of fiber distribution within the wheel structure. Uneven fiber arrangement can result in irregular hardness, inconsistent wear, and reduced abrasive effectiveness. Therefore, understanding how production processes maintain even fiber distribution is essential for achieving high-quality, durable, and efficient non-woven fiber wheels.

The properties of the fibers themselves play a significant role in achieving uniform distribution. Consistency in fiber length, thickness, and flexibility ensures that fibers can be arranged evenly during the production process. Variations in these characteristics may cause clumping or uneven layering, which compromises the wheel’s structural integrity. Manufacturers typically source high-quality fibers with tightly controlled specifications to reduce inconsistencies and facilitate a balanced distribution during assembly.

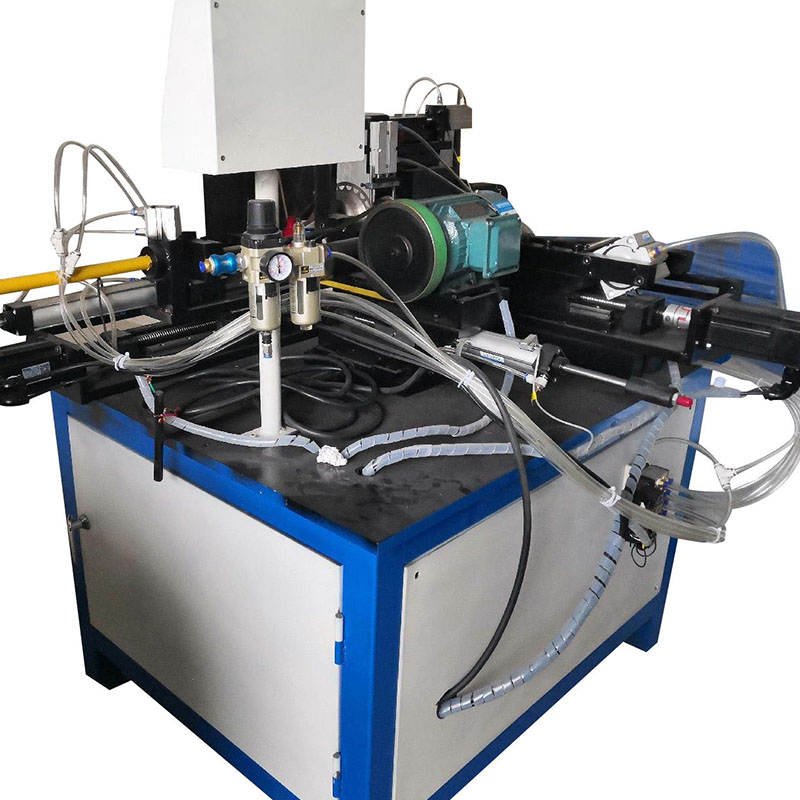

Modern production equipment for non-woven fiber wheels incorporates specialized design features to promote uniform fiber placement. Adjustable feeding systems allow fibers to be delivered at a controlled rate, preventing localized concentration. Rollers, combs, or vibration mechanisms are often employed to separate and evenly spread the fibers before bonding. Such equipment design ensures that fibers are distributed consistently throughout the wheel, creating uniform density and mechanical properties across the entire surface.

The compression and bonding stage is critical for maintaining uniform fiber arrangement. Controlled pressure during pressing ensures that fibers are compacted evenly, eliminating voids and preventing denser regions from forming. The choice of bonding agents and the method of their application also influence fiber alignment and stability. Uniform application of resin or adhesive promotes even fiber adhesion, maintaining the designed structure and preventing migration or shifting during curing.

Quality control measures are essential to verify and maintain uniform fiber distribution. Visual inspections, thickness measurements, and density checks can identify irregularities before the wheels proceed to final curing or packaging. Advanced systems may utilize real-time sensors or imaging technologies to monitor fiber placement continuously, allowing operators to make immediate adjustments if inconsistencies are detected. These monitoring techniques ensure that each wheel meets the required specifications for performance and reliability.

Uniform fiber distribution directly affects the functional performance of non-woven fiber wheels. Wheels with consistent fiber arrangement exhibit stable hardness, predictable wear rates, and even material removal during use. This uniformity enhances the efficiency of grinding or polishing tasks and prolongs the service life of the wheel. Inconsistent distribution, by contrast, can cause premature wear, uneven abrasion, and reduced safety during high-speed operation.

Non-Woven Fiber Wheel achieves uniform fiber distribution through a combination of high-quality raw materials, carefully designed production equipment, controlled compression and bonding processes, and rigorous quality monitoring. Each stage of production plays a critical role in ensuring that fibers are evenly arranged, resulting in consistent density, mechanical stability, and reliable performance. By focusing on these key aspects, manufacturers can produce non-woven fiber wheels that deliver suitable efficiency, longevity, and safety in a wide range of industrial applications.

The Full-Automatic Wire Twist Pen Brush Machine represents a significant leap in efficiency and precision for manufactur...

See Details

The CNC hydraulic cutting machine is a highly efficient, automated system designed to provide precision cutting for vari...

See Details

A polishing wire brush is an essential tool used in a variety of industries for achieving a smooth, polished surface on ...

See Details

High-Frequency Curved Wire Brush Segment MachineThe High-Frequency Curved Wire Brush Segment Machine is a specialized to...

See Details+86-18867586928

Contact Us