Cat:Brush Making Machine

The Full-Automatic Wire Twist Pen Brush Machine represents a significant leap in efficiency and precision for manufactur...

See DetailsIn today’s competitive manufacturing landscape, improving productivity without compromising quality is essential. This is particularly true in the brush manufacturing industry, where high demand for consistent, customizable, and cost-effective products drives companies to optimize their equipment performance. This article explores key strategies to enhance the production efficiency of Brush Making Machinery, ensuring faster output, reduced downtime, and better resource utilization.

Optimizing machine setup and programming

One of steps toward improving production efficiency is ensuring the Brush Making Machinery is correctly configured. Precise programming of brush specifications—such as hole patterns, tuft lengths, and bristle density—reduces the chance of errors or rework. Modern machines with touchscreen interfaces and automated adjustment features can significantly reduce setup time between different brush models, enabling faster batch transitions and operator intervention.

Investing in advanced automation features

Incorporating automation into the brush production process can drastically increase throughput. Features such as robotic arm loading, auto-feeding systems, and smart vision sensors enable machines to operate continuously with little human supervision. These upgrades not only speed up the overall manufacturing cycle but also reduce labor dependency and potential operator fatigue. Additionally, automated quality inspection systems help detect defects early, allowing for real-time corrections and preventing flawed products from reaching the end of the line.

Regular maintenance and preventive care

Downtime due to machine failure is one of the significant obstacles to efficient production. Implementing a proactive maintenance schedule ensures that all mechanical, electrical, and pneumatic components are in good condition. Regular lubrication, cleaning of the tufting and trimming mechanisms, and inspection of drive systems can extend the machine’s lifespan and reduce unplanned stoppages. Utilizing predictive maintenance tools, such as vibration sensors and thermal monitoring, can also help detect issues before they become serious.

Training and empowering operators

Well-trained operators are key to improving the performance of any manufacturing equipment. Providing hands-on training for operating, programming, and troubleshooting Brush Making Machinery empowers workers to respond swiftly to irregularities, reduce downtime, and perform minor repairs without needing external technicians. Clear standard operating procedures (SOPs) and process guidelines help ensure consistency across multiple shifts or teams, maintaining steady production rates.

Utilizing production data and analytics

Modern Brush Making Machinery often includes built-in data collection features. By analyzing production metrics such as output rate, cycle time, downtime frequency, and defect rates, manufacturers can identify inefficiencies and bottlenecks in real time. Implementing a centralized dashboard or manufacturing execution system (MES) allows for continuous monitoring and rapid decision-making. Data-driven insights can guide improvements in scheduling, resource allocation, and preventive maintenance planning.

Streamlining material flow and logistics

Even with high-performance machinery, production can be slowed by inefficient material handling. Ensuring a steady supply of raw materials, such as bristle stock, handles, and clips, to the machine is essential for maintaining continuous operation. Automated or semi-automated feeders, smart storage systems, and well-organized workstations contribute to smoother workflows. Reducing the distance between material supply points and the machinery helps eliminate unnecessary delays and operator movements.

Design standardization and process simplification

Standardizing brush designs where possible can streamline the production process and reduce setup changes. When different models share common dimensions or hole configurations, switching between batches becomes more efficient. Moreover, simplifying the production process by reducing steps or combining operations, such as trimming and cleaning, can cause significant time savings.

In conclusion, improving the productivity of Brush Making Machinery requires a multi-faceted approach, combining technology upgrades, skilled labor, data utilization, and thoughtful process design. By focusing on preventive maintenance, operator training, and automation, manufacturers can enhance machine efficiency and maintain a competitive edge in an increasingly demanding market.

The Full-Automatic Wire Twist Pen Brush Machine represents a significant leap in efficiency and precision for manufactur...

See Details

The Curved Brush Chip Cleaning Machine is engineered to solve common challenges in chip manufacturing, where cleanliness...

See Details

The Flower Head Wire Wheel Brush is a versatile and durable cleaning tool designed for use in various surface preparatio...

See Details

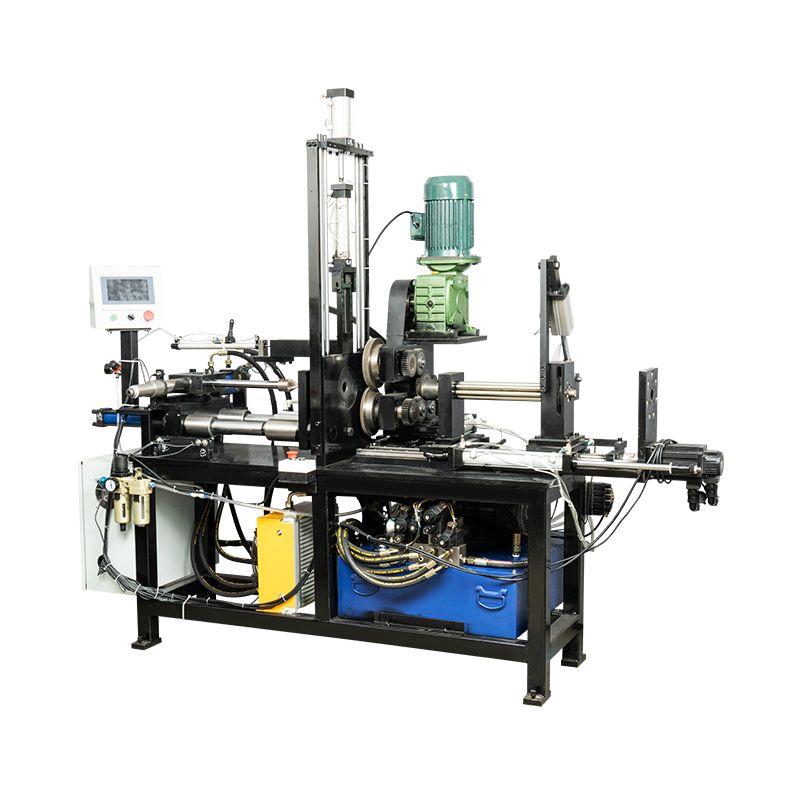

The Metal Material Twisting Wire Machine is a specialized industrial tool designed to twist and shape metal wires into v...

See Details+86-18867586928

Contact Us