Cat:Wire Wheel Brush

It features curved wire bristles that provide superior flexibility and uniform contact with the surface, ensuring effici...

See DetailsIn industries where brushes are essential, brush making machinery has revolutionized production by enabling higher efficiency, precision, and consistency. This article explores how these machines are designed to meet the growing demand for various types of brushes in the market, and why they are crucial for the brush manufacturing process.

Brush-making machinery plays a central role in the production of brushes used in a wide range of industries, from cleaning tools to automotive applications. These machines are designed to automate the process of brush manufacturing, which traditionally required a significant amount of manual labor. With advancements in technology, brush-making machinery can now produce brushes at higher speeds, with greater precision, and with fewer errors.

These machines can handle different stages of brush production, from bristle insertion to handle attachment, making the process much faster and more reliable. Whether producing small cosmetic brushes or large industrial brushes, brush-making machinery ensures that each product meets the required specifications for strength, durability, and performance.

One of the key advantages of brush-making machinery is its ability to improve the overall quality of the product. Manual brush production can often result in inconsistencies, where some brushes are not aligned properly or have uneven bristle lengths. Automated machinery, however, ensures that every brush produced meets precise quality standards.

With the help of brush-making machinery, manufacturers can control variables such as bristle length, density, and alignment to ensure consistency. This leads to better performance in the finished product, whether it’s a cleaning brush, a cosmetic brush, or a brush used in heavy-duty industrial applications.

Brush-making machinery is highly versatile and can be used to produce a wide range of brushes. Different types of brushes require different manufacturing processes, and modern machinery is capable of handling all these needs. Some common types of brushes made using these machines include:

Cleaning Brushes: These are used in homes, offices, and industries. Machinery can create brushes with different bristle stiffness for cleaning various surfaces.

Industrial Brushes: For use in automotive or other heavy industries, these brushes are designed to handle tough conditions and high demands.

Toothbrushes and Hair Brushes: The machinery can also be used to make personal care brushes like toothbrushes and hairbrushes, ensuring that they are durable and functional.

By tailoring the machinery for each type of brush, manufacturers can provide a diverse range of products to meet the demands of different markets.

Investing in brush-making machinery can help manufacturers save on labor costs while increasing overall output. Automated machines operate quickly and efficiently, producing large quantities of brushes without the need for constant supervision. This makes it easier for companies to scale production as demand increases.

Moreover, brush making machinery reduces the occurrence of defects and errors in production, meaning fewer products need to be discarded or repaired. This contributes to higher yield and less waste, further improving the overall cost efficiency of the manufacturing process.

While the initial investment in brush-making machinery can be significant, the long-term savings on labor, waste reduction, and increased productivity make it a wise choice for manufacturers looking to remain competitive in the market.

The key benefits of using brush-making machinery in the manufacturing industry are evident. These include:

Increased Speed and Efficiency: The machinery allows for the production of large quantities of brushes in a shorter time frame, speeding up delivery times to customers.

Consistency and Quality: With automated systems in place, each brush is made to the same high standard, reducing the risk of defects or inconsistencies.

Cost Savings: By reducing the need for manual labor and cutting down on material waste, manufacturers can achieve significant cost savings over time.

Flexibility: Brush-making machinery can be customized to handle different brush types, allowing manufacturers to serve multiple markets with the same equipment.

It features curved wire bristles that provide superior flexibility and uniform contact with the surface, ensuring effici...

See Details

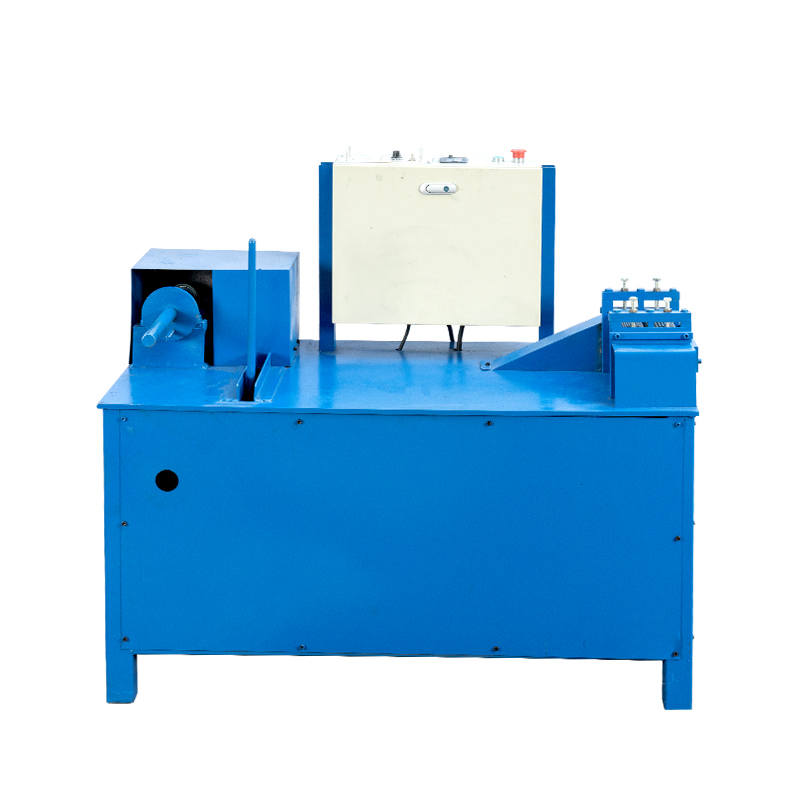

The Automatic Wire Cutting Machine is designed to streamline the process of wire-cutting, particularly in industries whe...

See Details

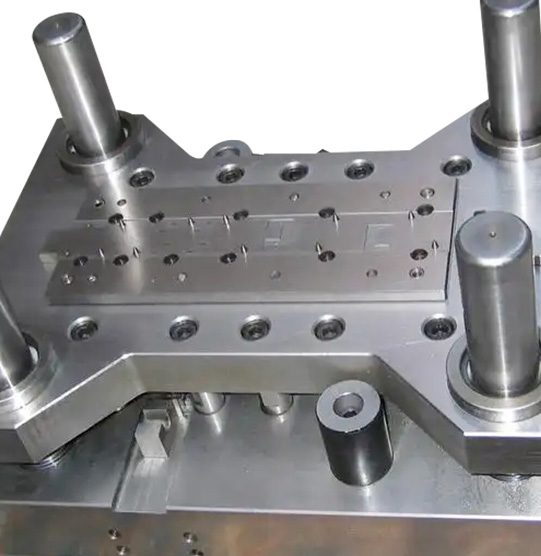

Metal drawing dies are essential tools in the metal forming process, especially when a sheet of metal needs to be reshap...

See Details

The CNC hydraulic cutting machine is a highly efficient, automated system designed to provide precision cutting for vari...

See Details+86-18867586928

Contact Us