Cat:Wire Wheel Brush

The Twisted Wire Bowl Wire Brush is a powerful and durable cleaning and finishing tool designed for heavy-duty industria...

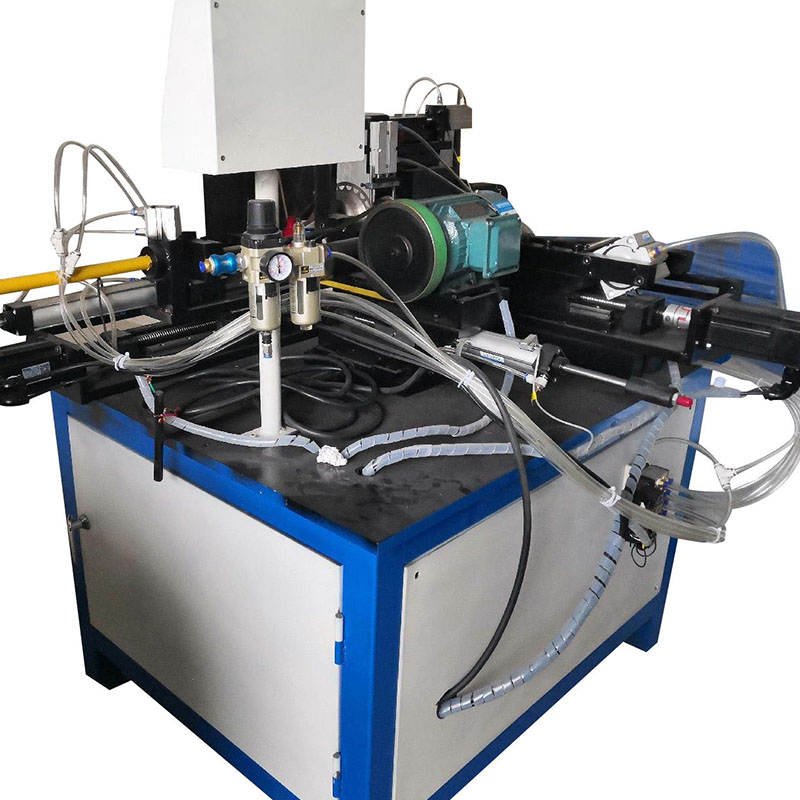

See DetailsA Non-Woven Fiber Wheel Production Equipment manufacturer emphasizes premium materials to ensure long-lasting performance and consistent output. Components such as rollers, motor systems, and fiber deposition mechanisms are crafted from corrosion-resistant metals and heat-tolerant polymers. Each part undergoes detailed testing for strength, wear resistance, and precision. By integrating superior materials, Non-Woven Fiber Wheel Production Equipment ensures reliable performance in continuous production environments, maintaining wheel uniformity and consistent abrasive properties.

The design of Non-Woven Fiber Wheel Production Equipment focuses on maximizing efficiency while maintaining precision. Automated fiber layering, adjustable compression rollers, and optimized wheel shaping mechanisms improve production speed without sacrificing quality. Control panels with intuitive interfaces and real-time monitoring enhance usability for operators. Well-designed Non-Woven Fiber Wheel Production Equipment allows manufacturers to produce high volumes of fiber wheels with consistent density, shape, and performance.

Efficient manufacturing is critical for Non-Woven Fiber Wheel Production Equipment. Automated feeding systems, precise fiber layering, and synchronized compression mechanisms maintain uniform wheel thickness and structure. Production workflows are calibrated to balance speed and accuracy, reducing material waste and minimizing defects. By streamlining processes, Non-Woven Fiber Wheel Production Equipment supports scalable production while maintaining product consistency.

Quality control is a key focus in Non-Woven Fiber Wheel Production Equipment. Machines are equipped with sensors to monitor wheel thickness, fiber density, and rotational balance. Deviations are detected early, allowing operators to make adjustments before defects occur. Systematic testing ensures that every wheel produced meets industry standards. A reliable Non-Woven Fiber Wheel Production Equipment system guarantees consistent abrasive performance, supporting applications across metal finishing, woodworking, and polishing industries.

Flexibility is a major advantage of Non-Woven Fiber Wheel Production Equipment. Manufacturers can adjust wheel size, fiber type, density, and abrasive properties to meet client specifications. This customization enables production of wheels suitable for diverse industrial tasks, from fine polishing to heavy-duty finishing. A Non-Woven Fiber Wheel Production Equipment system that allows such adaptability can serve a wide range of clients with different operational requirements.

Proper maintenance enhances the lifespan of Non-Woven Fiber Wheel Production Equipment. Regular cleaning of rollers, lubrication of moving parts, and calibration of sensors maintain consistent output. Factories provide detailed guidelines to minimize downtime and extend service life. Well-maintained Non-Woven Fiber Wheel Production Equipment ensures continuous operation, reducing costs and supporting long-term production schedules.

Environmental responsibility is increasingly important in Non-Woven Fiber Wheel Production Equipment. Manufacturers adopt energy-efficient motors, minimize fiber waste, and implement recyclable material use where possible. Reducing environmental impact while maintaining efficiency is crucial. A Non-Woven Fiber Wheel Production Equipment system that incorporates sustainability measures supports eco-friendly manufacturing without compromising wheel quality or production efficiency.

Timely distribution and adaptability are critical for Non-Woven Fiber Wheel Production Equipment. Coordinated logistics, inventory management, and secure shipping ensure that machines reach clients efficiently. Monitoring industry trends and client requirements allows manufacturers to upgrade equipment features and capabilities as needed. A Non-Woven Fiber Wheel Production Equipment system that adapts to market needs ensures that businesses stay competitive and responsive to evolving industrial demands.

The Twisted Wire Bowl Wire Brush is a powerful and durable cleaning and finishing tool designed for heavy-duty industria...

See Details

High-Frequency Curved Wire Brush Segment MachineThe High-Frequency Curved Wire Brush Segment Machine is a specialized to...

See Details

The Durable Non-Woven Fiber Wheel is an advanced tool designed for a variety of industrial surface finishing tasks. Craf...

See Details

A Precision CNC Bending Machine is a state-of-the-art piece of equipment designed for accurate and efficient metal sheet...

See Details+86-18867586928

Contact Us