Cat:Wire Wheel Brush

Made from twisted wire filaments, this brush is used extensively in industrial and maintenance applications for tasks th...

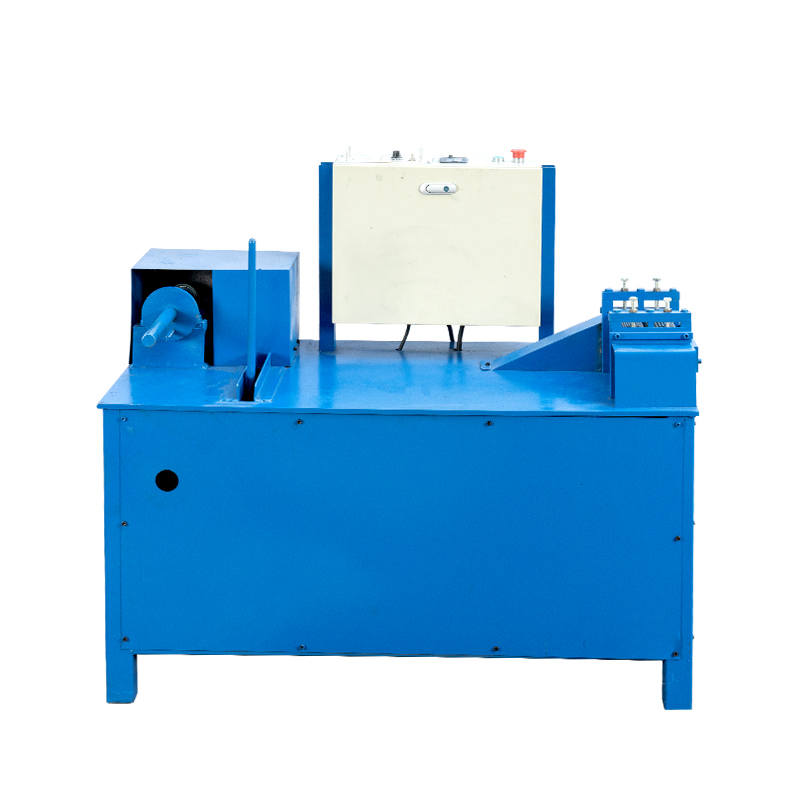

See DetailsA Automation Machinery And Equipment Producer prioritizes the use of high-quality materials to ensure durability and precise performance. Structural components, gears, and motor assemblies are constructed from corrosion-resistant metals and reinforced polymers. Each part undergoes rigorous testing for strength, load-bearing capacity, and heat tolerance. By integrating premium materials, a Automation Machinery And Equipment Producer ensures machines operate efficiently under demanding industrial conditions while maintaining long-term reliability.

Design is a central aspect of an Automation Machinery and Equipment Producer. Machines feature modular assemblies, adjustable workstations, and intuitive control interfaces to improve workflow and minimize operator error. Advanced designs include automated sensors, programmable logic controllers (PLC), and precision actuators. With these capabilities, an Automation Machinery and Equipment Producer delivers solutions that increase productivity, reduce downtime, and optimize industrial processes across various sectors.

Efficiency in production is critical for an Automation Machinery and Equipment Producer. Automated assembly lines, precision fabrication, and integrated testing protocols maintain uniform machine quality. Calibration ensures accurate movement, speed, and load distribution, minimizing deviations during operation. By streamlining production processes, an Automation Machinery And Equipment Producer can meet large-scale orders without compromising quality, supporting consistent industrial output for clients.

Quality assurance is essential for an Automation Machinery and Equipment Producer. Every machine undergoes a detailed inspection of mechanical accuracy, electrical performance, and operational stability. Sensors and diagnostic tools detect anomalies before machines leave the factory, ensuring that clients receive reliable equipment. Through systematic quality control, an Automation Machinery and Equipment Producer provides dependable machinery that meets industry standards and enhances operational efficiency.

A key strength of an Automation Machinery and Equipment Producer is its ability to offer customized solutions. Clients can request specialized machine configurations, tailored software programming, or custom tooling to meet specific production needs. Flexible design options allow the producer to serve industries ranging from automotive assembly to electronics manufacturing. By providing adaptable solutions, an Automation Machinery and Equipment Producer ensures that clients receive machinery optimized for their unique workflows.

Proper maintenance extends the lifespan of machines from an Automation Machinery and Equipment Producer. Regular inspection of moving parts, lubrication, and software updates prevents operational decline. Manufacturers provide detailed maintenance manuals and support services, helping clients maximize uptime. A well-maintained system from an Automation Machinery and Equipment Producer ensures consistent performance, reliability, and return on investment over time.

Sustainability is increasingly important for an Automation Machinery and Equipment Producer. Many manufacturers adopt energy-efficient motors, recyclable materials, and waste-minimization strategies in production. Designing durable, upgradeable machinery reduces environmental impact while maintaining high operational efficiency. An Automation Machinery And Equipment Producer that embraces sustainable practices supports eco-friendly industrial growth while meeting client expectations.

Timely delivery and market adaptability are crucial for an Automation Machinery and Equipment Producer. Coordinated logistics, inventory management, and installation support ensured machines reach clients efficiently. By monitoring emerging technologies, industry trends, and customer feedback, an Automation Machinery and Equipment Producer can adapt designs and functionalities to evolving market demands. This flexibility guarantees continued relevance and competitiveness in a dynamic industrial landscape.

Made from twisted wire filaments, this brush is used extensively in industrial and maintenance applications for tasks th...

See Details

The Full-Automatic Wire Twist Pen Brush Machine represents a significant leap in efficiency and precision for manufactur...

See Details

A metal-forming hydraulic press is a versatile and powerful machine commonly used in a variety of industries to form, sh...

See Details

The Segment Brushing Machine is an industrial tool designed for the efficient production of segmented wire brushes. Thes...

See Details+86-18867586928

Contact Us