Cat:Wire Wheel Brush

Twist Wire Pen-Type Wire Brush: Compact and Versatile Cleaning Tool The twist wire pen-type wire brush is a compact, han...

See DetailsNon-woven fiber wheels are essential tools for various metal finishing tasks. These versatile wheels, often composed of nylon or polyester fibers impregnated with abrasive materials, offer unique advantages over traditional abrasive tools. Their use spans industries such as automotive, aerospace, and manufacturing, providing efficient and effective metal surface preparation and finishing. This article explores how Non-Woven Fiber Wheels are used in metal finishing and why they are favored in this field.

Non-Woven Fiber Wheels are designed to provide a consistent finish without leaving visible scratches or damage to the surface. Unlike conventional abrasive wheels, which often cause aggressive grinding and heat buildup, these fiber wheels offer a gentler method of polishing. The unique structure of the fibers allows for a controlled, uniform finish, making them ideal for applications that require precision and delicate work.

One of the primary uses of Non-Woven Fiber Wheels is in surface preparation. These wheels are commonly employed for deburring, rust removal, and cleaning. In many industrial settings, removing unwanted surface contaminants is a crucial first step before coating, painting, or welding. Non-Woven Fiber Wheels effectively clean and prepare metal surfaces by gently removing rust, oxide layers, and other impurities. The ability to clean without damaging the underlying material makes them especially popular for use on sensitive or polished metals.

Non-Woven Fiber Wheels are also widely used for polishing metal surfaces. Whether it's for achieving a satin finish or a high-gloss shine, these wheels can provide a consistent, smooth result. The fibers in the wheel are impregnated with abrasives, such as aluminum oxide or silicon carbide, that polish the metal surface without the risk of over-polishing or creating an uneven texture. This makes them ideal for finishing products like automotive parts, kitchen appliances, and even decorative metal items.

One of the main reasons Non-Woven Fiber Wheels are so popular in metal finishing is their versatility. These wheels come in different grades and sizes, making them suitable for a wide range of tasks. For instance, coarse-grade wheels are perfect for heavy-duty deburring and cleaning, while finer grades can be used for polishing and achieving smooth finishes. This flexibility allows manufacturers to select the right tool for each stage of the finishing process, helping to streamline operations and achieve high-quality results.

In comparison to traditional abrasive tools, Non-Woven Fiber Wheels offer several key benefits. They are gentler on surfaces, reducing the risk of scratches, gouges, or heat marks. Additionally, they provide a consistent finish over a longer period of time, which is crucial for maintaining product quality in mass production environments. These wheels also produce less dust and debris, making them a cleaner option for workplaces.

The durability and long lifespan of Non-Woven Fiber Wheels also contribute to their growing popularity. Unlike other abrasive materials that wear down quickly, these fiber wheels can handle prolonged use without degrading in performance. This makes them a cost-effective solution for industries that require constant, high-quality metal finishing.

When selecting a Non-Woven Fiber Wheel for metal finishing, it is essential to consider the type of metal, the desired finish, and the specific task at hand. Coarse, medium, and fine wheels each serve a different purpose. It's also important to choose the correct size and shape of the wheel to match the application, whether it's for cleaning, polishing, or surface preparation.

In conclusion, Non-Woven Fiber Wheels are indispensable in the world of metal finishing. Their ability to deliver precise, consistent results without damaging the workpiece makes them ideal for a variety of tasks, from deburring and cleaning to polishing and surface preparation. As industries continue to demand higher standards of quality, Non-Woven Fiber Wheels will remain a go-to tool for metalworkers worldwide

Twist Wire Pen-Type Wire Brush: Compact and Versatile Cleaning Tool The twist wire pen-type wire brush is a compact, han...

See Details

It features curved wire bristles that provide superior flexibility and uniform contact with the surface, ensuring effici...

See Details

A polishing wire brush is an essential tool used in a variety of industries for achieving a smooth, polished surface on ...

See Details

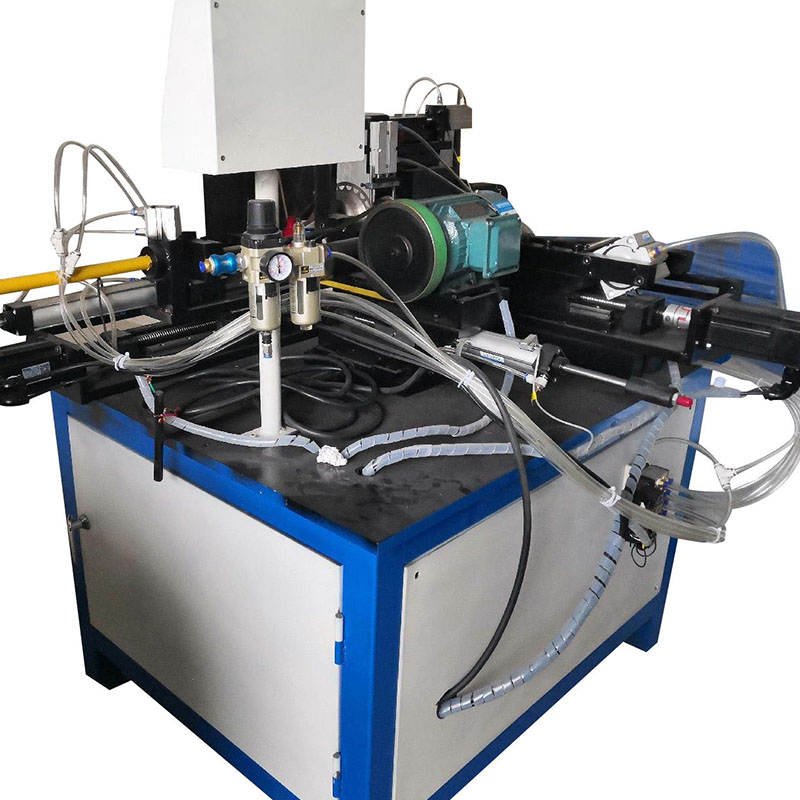

High-Frequency Curved Wire Brush Segment MachineThe High-Frequency Curved Wire Brush Segment Machine is a specialized to...

See Details+86-18867586928

Contact Us