Cat:Wire Wheel Brush

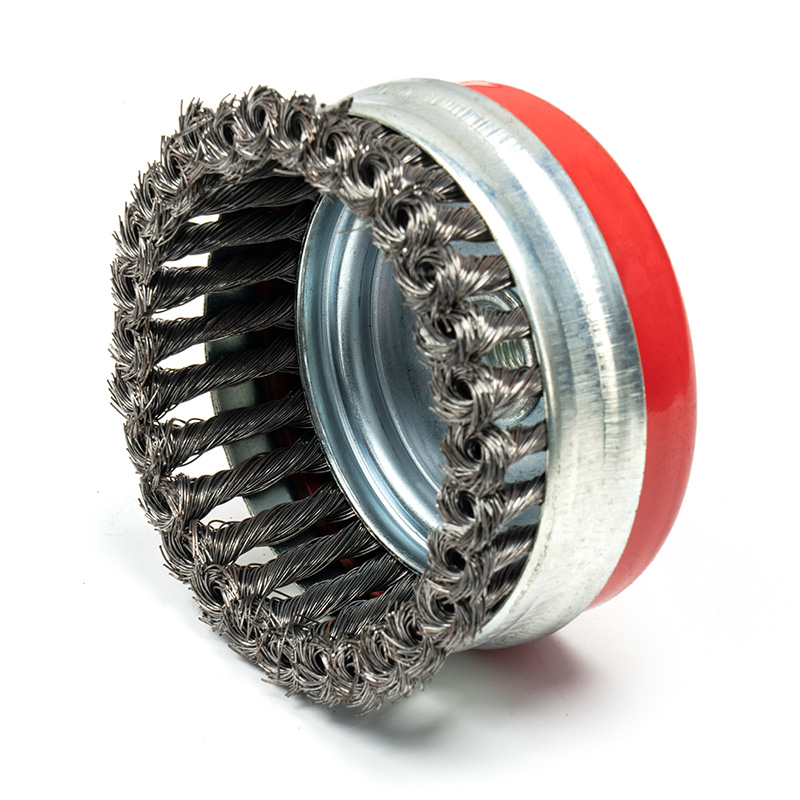

Twisted Wire Cup Wire Brush: Robust Cleaning and Surface Preparation Tool The twisted wire cup wire brush is a versatile...

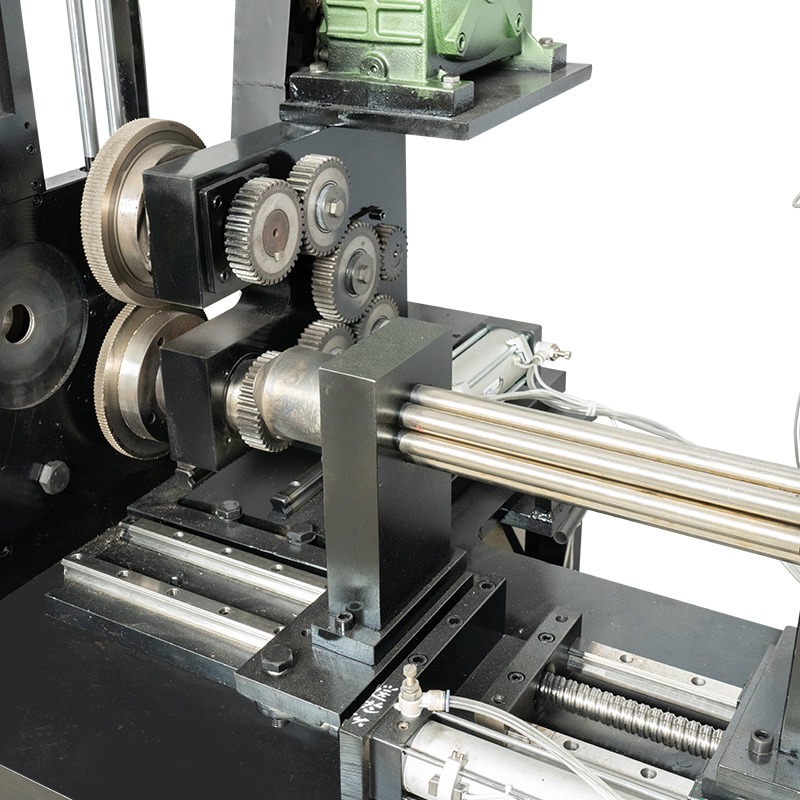

See DetailsA Brush Making Machinery Supplier focuses on using premium materials to ensure durability and precise operation. Components such as gears, motors, and bristle-holding mechanisms are constructed from corrosion-resistant metals and reinforced polymers. Each part undergoes detailed testing for wear resistance, heat tolerance, and mechanical stability. By incorporating superior materials, a Brush Making Machinery Supplier ensures that machines maintain consistent performance, producing brushes with uniform quality for various applications.

Design is a key factor for a Brush Making Machinery Supplier. Machines are engineered for ergonomic handling, precise bristle insertion, and adjustable production settings. Features like programmable controls, automated feeding systems, and real-time monitoring enhance productivity and reduce human error. A well-designed Brush Making Machinery Supplier machine allows manufacturers to produce brushes efficiently while maintaining high accuracy and consistent quality standards.

Efficiency and consistency are essential for a Brush Making Machinery Supplier. Automated assembly, precise bristle alignment, and synchronized mechanical movements ensure uniform brush density and shape. Production workflows are optimized to balance speed and precision, minimizing material waste and defects. By implementing streamlined processes, a Brush Making Machinery Supplier can meet both large-scale industrial demands and smaller specialized orders without compromising quality.

Quality control is crucial for a Brush Making Machinery Supplier. Each machine is inspected for mechanical accuracy, operational stability, and safety compliance. Sensors monitor bristle alignment, insertion depth, and brush density during production. Any deviations are corrected immediately to maintain product consistency. With systematic quality checks, a Brush Making Machinery Supplier guarantees that every machine delivered can produce brushes that meet industry standards and client expectations.

Customization is a significant advantage of a Brush Making Machinery Supplier. Clients can request machines tailored to specific brush sizes, bristle types, and production volumes. Optional features include adjustable bristle spacing, specialized feed systems, and integrated packaging units. Offering flexible solutions allows a Brush Making Machinery Supplier to serve diverse industries such as household cleaning, industrial maintenance, and cosmetic brushes, ensuring machines meet unique operational needs.

Proper maintenance is vital for prolonging the life of machines from a Brush Making Machinery Supplier. Regular cleaning, lubrication, and calibration prevent wear and maintain precision. Detailed maintenance guidelines provided by the supplier help operators sustain optimal performance. A well-maintained Brush Making Machinery Supplier machine continues to deliver consistent results, reducing downtime and operational costs for manufacturers.

Sustainability is increasingly important for a Brush Making Machinery Supplier. Many suppliers implement energy-efficient motors, recyclable components, and waste reduction techniques in production. Machines designed for longevity and upgradeability minimize environmental impact while maintaining operational efficiency. A Brush Making Machinery Supplier that prioritizes eco-friendly practices supports sustainable manufacturing while ensuring high-quality output.

Timely delivery and market responsiveness are critical for a Brush Making Machinery Supplier. Coordinated logistics, secure packaging, and inventory management ensure machines reach clients efficiently. Monitoring emerging technologies, client feedback, and market trends allows the supplier to update machine features and adapt designs for evolving industry needs. This adaptability ensures that a Brush Making Machinery Supplier remains competitive and relevant in a dynamic manufacturing landscape.

Twisted Wire Cup Wire Brush: Robust Cleaning and Surface Preparation Tool The twisted wire cup wire brush is a versatile...

See Details

Made from twisted wire filaments, this brush is used extensively in industrial and maintenance applications for tasks th...

See Details

It features curved wire bristles that provide superior flexibility and uniform contact with the surface, ensuring effici...

See Details

The pen-shaped twisted wire brush is a versatile, compact tool designed for cleaning, polishing, and surface preparation...

See Details+86-18867586928

Contact Us