Cat:Wire Wheel Brush

This brush is particularly useful in wire bending and shaping processes, where it helps to remove contaminants, debris, ...

See DetailsEffect of High Speed on Wire Fatigue and Brush Integrity

Operating a Wire Wheel Brush at high rotational speeds introduces significant mechanical stress on the bristles due to centrifugal force. As the wheel spins faster, each wire is pulled outward, and the tension increases proportionally with speed. This added force can make individual wires more susceptible to fatigue, especially if the brush is poorly manufactured, unevenly worn, or used inappropriately for the material at hand. The breakage often results not only in reduced cleaning or finishing efficiency but also poses serious safety hazards for machine operators. Flying wires can cause injuries or damage to surrounding equipment if proper containment or safety gear is not in place. Therefore, speed must always be matched with brush specification to ensure safe use and suitable longevity.

Material and Structural Design Considerations

The risk of wire shedding is closely linked to the type of material used in the brush and how it’s constructed. Carbon steel wires, for instance, may offer aggressive abrasion but are more prone to breakage when operating near their rated speeds. Stainless steel bristles offer more flexibility and corrosion resistance, which may slightly improve performance at higher RPMs. However, regardless of material, tightly wound, knotted, or crimped wires generally perform better under stress because they offer additional support and prevent wires from freely flaring outward. Brushes that are too lightweight or have loosely packed bristles tend to deform faster and shed wires more readily under high-speed conditions. Selecting brushes specifically rated for high RPM use and designed with reinforced backing plates and strong wire anchoring systems is essential in mitigating failure.

Improper Brush Selection and Over-Speeding Issues

One common cause of wire breakage is using a brush beyond its rated RPM. Each brush is designed with a safe speed, often listed on the packaging or the tool itself. Exceeding this speed, even slightly, can cause structural instability and increase the likelihood of wire ejection. Additionally, using a small-diameter brush at speeds suited for larger brushes intensifies stress at the wire roots. Operators may also select the wrong brush type for the application—for instance, using a light-duty brush for heavy rust or weld slag removal, forcing the brush to work harder than it was designed for. This mismatch causes excessive heat, wire bending, and eventually snapping. Matching the brush type, size, and wire stiffness to the intended task and equipment is crucial for safe and effective operation.

Routine Maintenance and Safety Measures

Routine inspection and maintenance are vital in preventing wire shedding over time. Brushes should be checked for signs of imbalance, wire thinning, rust, or deformation before and after each use. If a brush shows signs of excessive wear, it should be replaced rather than forced into continued service. Using protective barriers like wheel guards, operator shields, and personal protective equipment (PPE) such as gloves, goggles, and face shields helps reduce the risk from flying wire fragments. In industrial settings, using automated or enclosed brushing systems further reduces human exposure to potential hazards, especially when operating at higher RPMs.

Although high rotational speeds enhance material removal efficiency, they also increase the mechanical strain on brush components. The Wire Wheel Brush, when used incorrectly or outside its rated specifications, is more likely to experience wire breakage or deformation. However, with careful brush selection, appropriate speed matching, proper mounting, operator training, and ongoing maintenance, the risks associated with high-speed use can be significantly reduced. Ensuring both productivity and safety requires a balanced approach that respects the mechanical limits of the tools in use.

This brush is particularly useful in wire bending and shaping processes, where it helps to remove contaminants, debris, ...

See Details

Featuring a bowl-shaped configuration and twisted wire bristles, this brush is suitable for industrial and automotive ap...

See Details

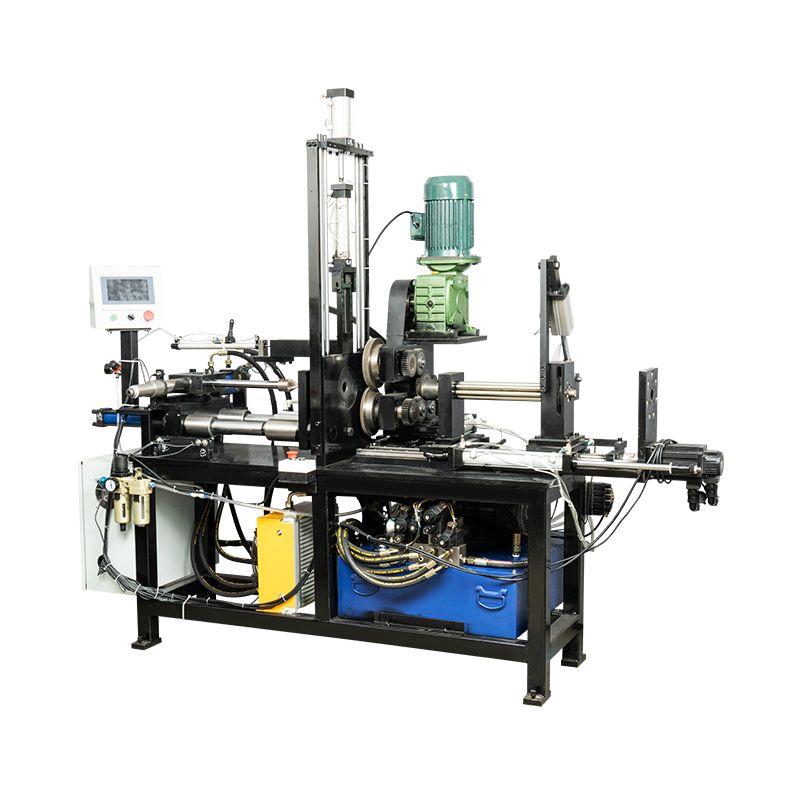

The Curved Brush Chip Cleaning Machine is engineered to solve common challenges in chip manufacturing, where cleanliness...

See Details

The Rust Removal Wire Brush is an essential tool designed for efficient rust removal, surface preparation, and polishing...

See Details+86-18867586928

Contact Us