Cat:Wire Wheel Brush

Made from twisted wire filaments, this brush is used extensively in industrial and maintenance applications for tasks th...

See DetailsFinishing and metalworking, selecting the appropriate abrasive tool is crucial for achieving desired results efficiently. Non-Woven Fiber Wheels are widely used due to their flexibility and versatility, but how do they compare to traditional abrasive wheels, such as conventional grinding wheels or sandpaper-based cloth wheels? Understanding the differences in efficiency, material removal rate, surface finish, and adaptability helps users choose the suitable tool for specific applications.

Material Removal Efficiency

Non-woven fiber Wheels are designed with a dense network of synthetic fibers impregnated with abrasive grains. This structure allows for gentle, consistent material removal without aggressive cutting. Compared to conventional grinding wheels, which remove material quickly but can leave deep scratches or require more careful handling, fiber wheels offer a controlled and uniform abrasion. While the removal rate may be slower than that of a high-speed grinding wheel, the reduced risk of over-cutting or damaging delicate surfaces can result in higher overall productivity in finishing tasks where precision is key.

Surface Finish Quality

One of the major advantages of Non-Woven Fiber Wheels is their ability to produce smooth, uniform finishes. Unlike traditional sandpaper or grinding wheels that may leave visible scratch patterns, fiber wheels conform to the surface contours and provide a consistent finish even on complex geometries or curved surfaces. This makes them particularly effective for deburring, polishing, or blending surface imperfections. In comparison, abrasive cloth wheels may require multiple grit changes and additional passes to achieve a similar level of smoothness, increasing labor and time.

Flexibility and Adaptability

Flexibility is another factor where Non-Woven Fiber Wheels excel. The fibrous structure allows the wheel to adapt to irregular shapes, corners, and edges without damaging the workpiece. Conventional rigid grinding wheels, while efficient for flat surfaces and heavy material removal, are less adaptable and may not reach tight spots or contours without specialized tooling. Fiber wheels provide a balance between adaptability and abrasive effectiveness, making them suitable for both rough and fine finishing in a single tool.

Durability and Longevity

In terms of lifespan, Non-Woven Fiber Wheels often demonstrate consistent wear over time, maintaining performance until the wheel is fully consumed. Grinding wheels may wear unevenly, especially under improper speed or pressure, while sandpaper cloth wheels may tear or clog, requiring frequent replacement. This durability contributes to more predictable efficiency and reduced downtime during production processes.

Safety and Ease of Use

Fiber wheels are generally safer to operate because their flexible structure reduces the risk of sparks or sudden breakage that can occur with rigid grinding wheels. They generate less heat during use, which reduces thermal damage to both the workpiece and operator. This makes Non-Woven Fiber Wheels particularly advantageous in environments where safety and material integrity are priorities.

Choosing the Right Abrasive Tool

While traditional grinding wheels and sandpaper-based cloth wheels provide rapid material removal, Non-Woven Fiber Wheels offer controlled abrasion, good surface finish, and greater adaptability to complex shapes. They may have a slower removal rate, but the benefits in precision, consistency, and reduced risk of damage make them ideal for finishing, polishing, and deburring applications. Understanding these differences allows operators to select the efficient tool for each task, optimizing both quality and productivity in their work processes.

Made from twisted wire filaments, this brush is used extensively in industrial and maintenance applications for tasks th...

See Details

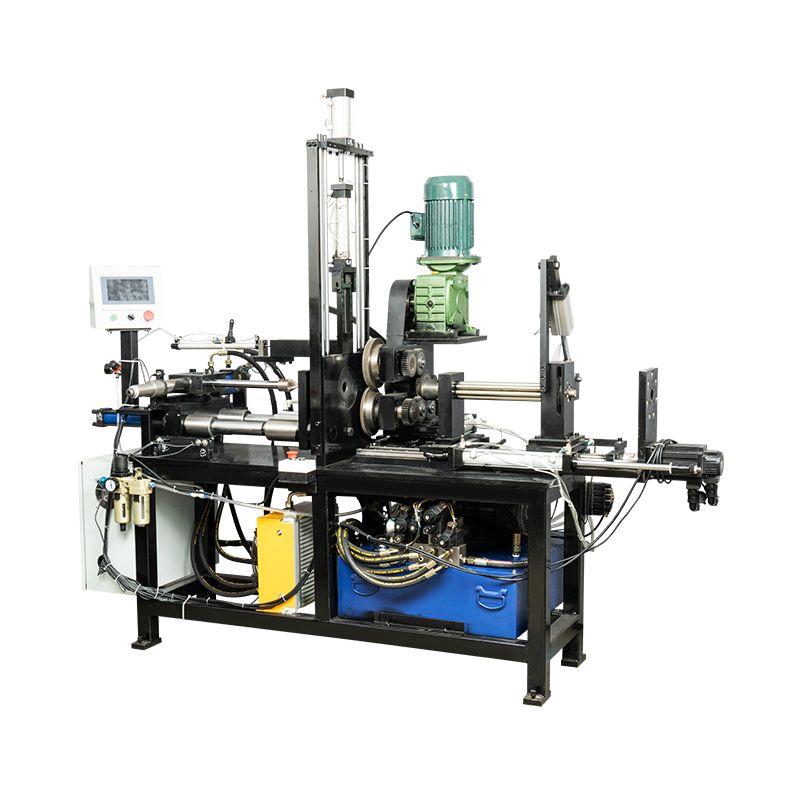

The Curved Brush Chip Cleaning Machine is engineered to solve common challenges in chip manufacturing, where cleanliness...

See Details

A CNC bending machine is a high-precision piece of equipment designed to bend metal sheets and plates with high accuracy...

See Details

The Precision Punching Press is an advanced, high-performance machine designed for efficient and precise punching, shear...

See Details+86-18867586928

Contact Us