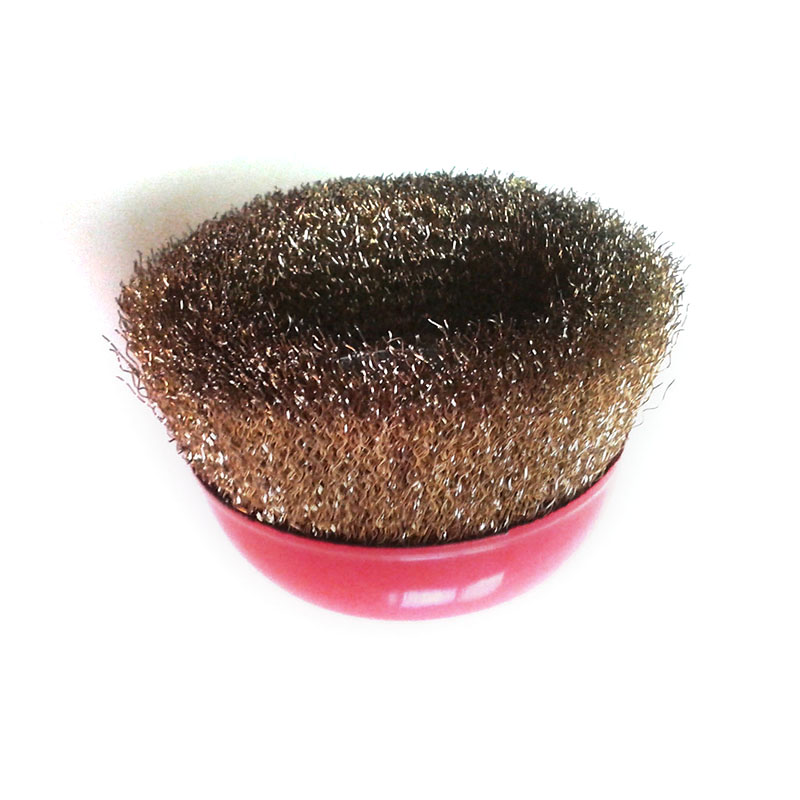

Cat:Wire Wheel Brush

The Bowl Wire Brush is a versatile and durable cleaning tool designed for various surface preparation tasks, including r...

See DetailsIntroduction to Speed and Polishing Efficiency

The working speed of abrasive tools significantly influences the quality and efficiency of polishing processes. For Non-Woven Fiber Wheels, which are commonly used in surface finishing and cleaning applications, adjusting rotational speed can alter the wheel’s interaction with the workpiece. Understanding how speed affects polishing outcomes is crucial for optimizing results, prolonging tool life, and ensuring consistent surface quality in industrial operations.

Relationship Between Speed and Abrasive Action

At different speeds, the Non-Woven Fiber Wheel exhibits varying abrasive behaviors. Higher speeds increase the number of fiber and abrasive particle contacts per unit time, which generally enhances material removal rates and polishing aggressiveness. This can cause faster smoothing of rough surfaces or removal of oxidation and contaminants. However, excessively high speeds may generate more heat due to friction, potentially causing surface discoloration, warping, or damage, especially on heat-sensitive materials.

Effect of Low Speed on Surface Finish

Operating the wheel at lower speeds typically results in gentler polishing action. The reduced rotational velocity limits heat buildup and abrasive aggression, making it suitable for delicate surfaces or fine finishing tasks. While the polishing process may take longer at low speeds, it offers better control and reduces the risk of over-polishing or uneven surface textures. For applications requiring a satin or matte finish, slower speeds can help achieve the desired subtle surface modification without damaging the substrate.

Balancing Speed for Suitable Results

Finding a suitable working speed for a Non-Woven Fiber Wheel involves balancing material removal efficiency with surface quality and tool longevity. Medium speeds often provide the compromise by delivering sufficient abrasive force while reducing thermal and mechanical stresses. This balance helps maintain the wheel’s structure and abrasive properties over longer periods, reducing wear and avoiding premature replacement. Operators should consider the specific material characteristics and polishing goals when selecting the appropriate speed range.

Impact on Wheel Wear and Tool Life

Working speed also influences the wear rate of Non-Woven Fiber Wheels. Higher speeds tend to accelerate fiber abrasion and abrasive grain loss due to increased mechanical stress and heat generation. This can shorten the wheel’s effective lifespan and increase operating costs. Conversely, running the wheel at too low a speed may cause inefficient polishing, requiring longer operational times that also contribute to wear. Careful speed adjustment, combined with proper pressure and technique, helps improve tool durability.

Safety Considerations Related to Speed

Beyond polishing performance, working speed affects operator safety. Exceeding the manufacturer’s recommended speed can cause mechanical failure or wheel disintegration, posing serious hazards. Maintaining speeds within specified limits ensures that the wheel operates within its designed mechanical tolerance, preventing accidents. Additionally, proper use of personal protective equipment (PPE) and adherence to safety protocols are essential when working with Non-Woven Fiber Wheels at any speed.

Conclusion: Speed Optimization Enhances Polishing with Non-Woven Fiber Wheels

In conclusion, the working speed of a Non-Woven Fiber Wheel has a profound impact on polishing effectiveness, surface finish quality, and tool lifespan. Adjusting speed allows operators to tailor abrasive action to specific materials and applications, balancing efficiency and care. Understanding and applying suitable speed settings is key to achieving consistent, high-quality polishing results while ensuring safe and economical use of Non-Woven Fiber Wheels in various industrial environments.

The Bowl Wire Brush is a versatile and durable cleaning tool designed for various surface preparation tasks, including r...

See Details

The Rust Removal Wire Brush is an essential tool designed for efficient rust removal, surface preparation, and polishing...

See Details

The Durable Non-Woven Fiber Wheel is an advanced tool designed for a variety of industrial surface finishing tasks. Craf...

See Details

The Abrasion-Resistant Non-Woven Fiber Wheel is an advanced abrasive tool designed for a wide range of metalworking appl...

See Details+86-18867586928

Contact Us