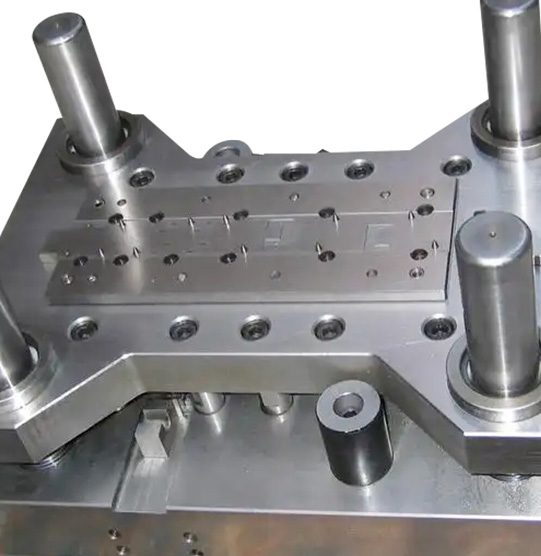

Cat:Stamping Die

Metal drawing dies are essential tools in the metal forming process, especially when a sheet of metal needs to be reshap...

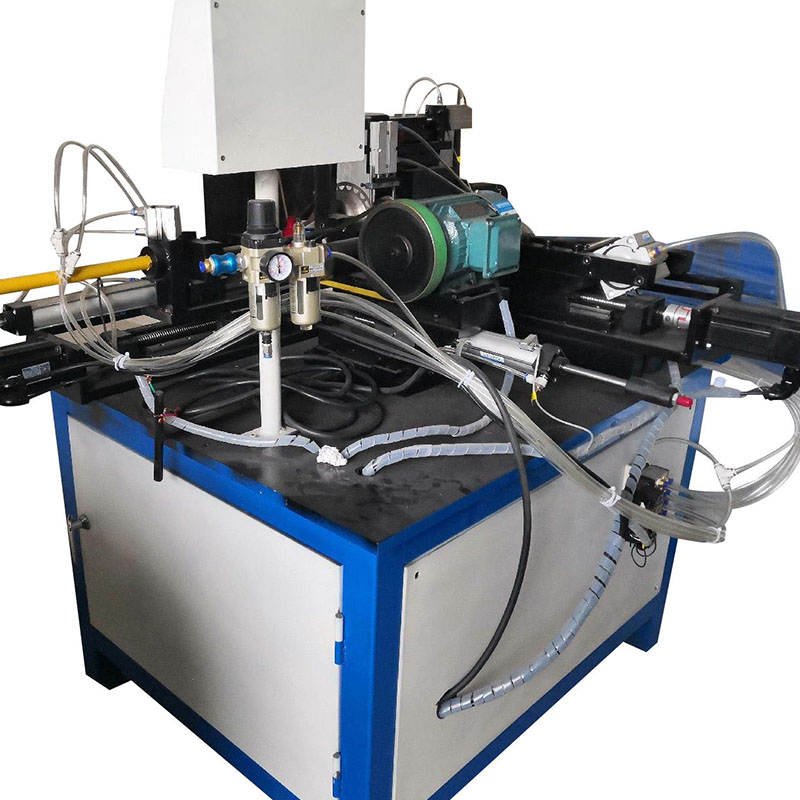

See DetailsThe Automated Sheet Metal Bending Machine stands out for its ability to deliver high quality precision and consistency. Unlike traditional methods, these machines eliminate the human error factor, ensuring that every bend is made to exact specifications. This is particularly beneficial for industries where precision is critical, such as aerospace and automotive manufacturing. Our Desktop CNC Wire Bender, for instance, is designed to provide high-precision bends with minimal operator intervention, ensuring that each part meets the stringent quality standards required by these sectors.

One of significant advantages of Automated Sheet Metal Bending Machines is the boost in productivity they offer. These machines can work around the clock, with minimal downtime for maintenance or operator fatigue. This continuous operation guides to a significant increase in output, which is a game-changer for businesses looking to scale up their production capabilities. Our Industrial Rebar Bending Machine is a testament to this, as it can handle large volumes of rebar with speed and accuracy, making it an invaluable asset in construction and infrastructure projects.

Automated Sheet Metal Bending Machines also offer substantial cost savings by reducing the need for manual labor. The machines can perform tasks that were once done by multiple workers, thus lowering labor costs. Moreover, by automating the bending process, we can significantly improve workplace safety. The risk of injury from manual bending operations is greatly reduced, as operators are no longer in close proximity to the bending area. Our Desktop CNC Wire Bender is engineered with safety features that protect operators from potential hazards, making it a preferred choice for workshops that prioritize safety.

Another key advantage of Automated Sheet Metal Bending Machines is their ability to handle a wide range of materials and thicknesses. This flexibility allows manufacturers to produce a diverse range of products without the need for multiple machines. Our Industrial Rebar Bending Machine is designed to accommodate various rebar sizes and shapes, making it a versatile tool for construction projects that require customized reinforcement solutions.

In today's environmentally conscious world, energy efficiency is a critical consideration. Automated Sheet Metal Bending Machines are designed to consume less energy compared to traditional methods, making them a more sustainable choice. By reducing energy consumption, manufacturers can lower their carbon footprint and contribute to global efforts to combat climate change. Our Automated Sheet Metal Bending Machines are built with energy-saving components, ensuring that they operate efficiently while minimizing environmental impact.

As a Wire Brush Equipment Manufacturer, we understand the importance of staying ahead in a competitive market. The adoption of Automated Sheet Metal Bending Machines is not just a trend; it's a strategic move that can significantly enhance a company's production capabilities. By leveraging the precision, efficiency, safety, and sustainability offered by these machines, manufacturers can achieve new heights in productivity and quality. Whether it's a Desktop CNC Wire Bender for intricate wire work or an Industrial Rebar Bending Machine for large-scale construction projects, the right Automated Sheet Metal Bending Machine can be the key to unlocking greater potential in manufacturing.

Metal drawing dies are essential tools in the metal forming process, especially when a sheet of metal needs to be reshap...

See Details

The Metal Joining Welder is an advanced tool designed to meet the demanding needs of industries that require reliable an...

See Details

The Rust Removal Wire Brush is an essential tool designed for efficient rust removal, surface preparation, and polishing...

See Details

High-Frequency Curved Wire Brush Segment MachineThe High-Frequency Curved Wire Brush Segment Machine is a specialized to...

See Details+86-18867586928

Contact Us