Cat:Wire Wheel Brush

Featuring a bowl-shaped configuration and twisted wire bristles, this brush is suitable for industrial and automotive ap...

See DetailsIn the ever-evolving landscape of manufacturing, the quest for better quality control and efficiency has led to a surge in the development and integration of making machinery and industrial equipment. Companies are now looking to harness the power of machinery and industrial machine automation to streamline their processes, ensuring that their products meet high standards of quality and are produced at a faster pace.

The integration of making machinery and industrial equipment is not just a trend; it's a necessity for businesses aiming to stay competitive in a global market. By incorporating advanced machinery into their production lines, companies can achieve a higher level of precision and consistency, which are crucial for quality control. Moreover, the adoption of industrial machine automation allows for the reduction of human error, which is a common culprit in quality issues.

One of the key benefits of integrating making machinery into the production process is the ability to monitor and control the manufacturing process in real-time. With the help of sensors and data analytics, industrial equipment can now provide feedback on the performance of the machinery, allowing for immediate adjustments to be made. This level of oversight is a game-changer for quality control, as it enables manufacturers to catch and correct issues before they result in defective products.

Efficiency is another area where making machinery and industrial equipment shine. By automating repetitive tasks, companies can reduce labor costs and increase output. Industrial machine automation not only speeds up the production process but also frees up human workers to focus on more complex tasks that require creativity and problem-solving skills. This shift in labor allocation can cause a more productive and engaged workforce, which in turn contributes to better quality control.

The integration of making machinery and industrial equipment also opens up new possibilities for customization and flexibility in production. With advanced machinery, manufacturers can quickly switch between different product lines or even produce small batches of customized items without significant downtime. This agility is particularly valuable in industries where consumer preferences change rapidly, and the ability to adapt quickly can be the difference between success and obsolescence.

As companies look to invest in making machinery and industrial equipment, they must also consider the training and support needed to ensure a smooth transition to a more automated workflow. This includes not only the technical training for operators but also the development of new protocols for quality control and maintenance. By investing in both the machinery and the people who will use it, companies can ensure that they were abundant in the benefits of their new equipment.

The integration of making machinery and industrial equipment is a strategic move that can significantly improve both quality control and efficiency in manufacturing. By leveraging the power of industrial machine automation, companies can achieve higher standards of quality, increase production speed, and remain agile in the face of changing market demands. As the industry continues to evolve, the adoption of advanced making machinery and industrial equipment will be a key differentiator for those who wish to guide the pack in terms of product advanced and operational efficiency.

Featuring a bowl-shaped configuration and twisted wire bristles, this brush is suitable for industrial and automotive ap...

See Details

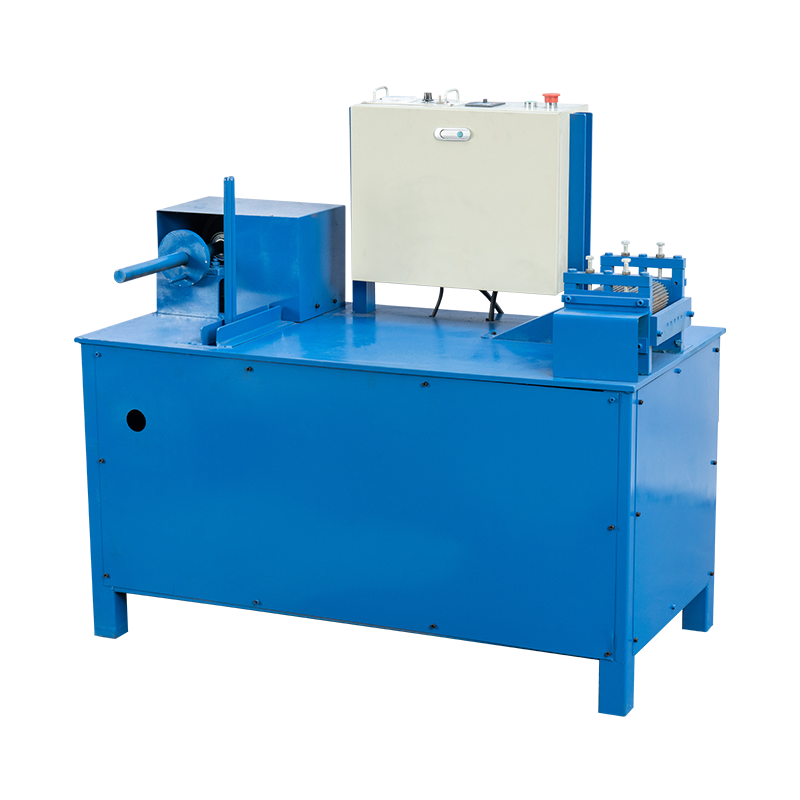

The Wire Bending Machine is an essential piece of equipment in the production of steel wire brushes, where precision, ef...

See Details

The CNC high precision bending machine is designed for bending metal sheets, such as steel, aluminum, and stainless stee...

See Details

The Precision Punching Press is an advanced, high-performance machine designed for efficient and precise punching, shear...

See Details+86-18867586928

Contact Us