Cat:Wire Wheel Brush

Twist Wire Pen-Type Wire Brush: Compact and Versatile Cleaning Tool The twist wire pen-type wire brush is a compact, han...

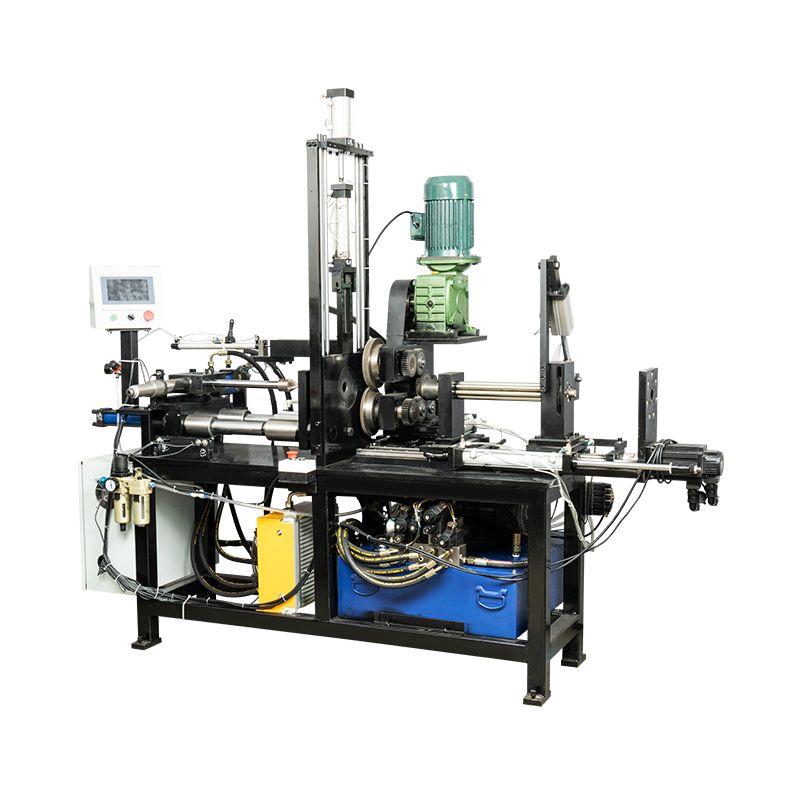

See DetailsThe durability of Non-Woven Fiber Wheel Production Equipment is a key performance indicator that manufacturers must consider to ensure the longevity and reliability of their production lines. Durability in this context refers to the ability of the equipment to withstand the rigors of continuous use, maintain high levels of performance, and resist wear and tear over an extended period. The importance of Non-Woven Fiber Wheel Production Equipment durability cannot be overstated, as it directly impacts the cost-effectiveness, production efficiency, and overall profitability of manufacturing operations.

To evaluate the durability of Non-Woven Fiber Wheel Production Equipment, several factors must be taken into account. These include the quality of materials used in construction, the robustness of the design, the precision of the manufacturing process, and the effectiveness of maintenance protocols. High-quality materials are essential for ensuring that the equipment can endure the physical stress of constant operation without succumbing to fatigue or failure. The design of the Non-Woven Fiber Wheel Production Equipment must also be carefully considered to ensure that it is not only efficient in operation but also resistant to the corrosive effects of the materials it processes.

The manufacturing process itself plays a crucial role in determining the durability of Non-Woven Fiber Wheel Production Equipment. Precision engineering ensures that all components fit together seamlessly, reducing the likelihood of mechanical failure due to misalignment or poor assembly. Additionally, advanced manufacturing techniques can enhance the strength of the equipment by optimizing the distribution of materials and eliminating structural weaknesses.

Maintenance is another critical aspect of Non-Woven Fiber Wheel Production Equipment durability. Regular servicing and inspections can identify potential issues before they become critical, thereby prolonging the life of the equipment. Manufacturers must develop comprehensive maintenance schedules that take into account the specific needs of their Non-Woven Fiber Wheel Production Equipment, including the frequency of cleaning, lubrication, and replacement of wear parts.

The environment in which the Non-Woven Fiber Wheel Production Equipment operates can also have a significant impact on its durability. Exposure to extreme temperatures, humidity, and corrosive substances can degrade the equipment over time, so it is essential to implement protective measures such as enclosures, coatings, and climate control systems.

Innovations in technology are continually being developed to enhance the durability of Non-Woven Fiber Wheel Production Equipment. For example, the incorporation of smart sensors can monitor the equipment's performance in real time, providing early warnings of potential issues that could cause failure. Additionally, the use of advanced materials such as high-strength alloys and composites can improve the resistance to wear and corrosion.

Training for operators is also an essential component of maintaining the durability of Non-Woven Fiber Wheel Production Equipment. Proper use and handling of the equipment can significantly reduce the risk of damage and extend its service life. Manufacturers must invest in comprehensive training programs that cover all aspects of equipment operation, maintenance, and troubleshooting.

In conclusion, the durability of Non-Woven Fiber Wheel Production Equipment is a multifaceted issue that requires a holistic approach. By focusing on materials quality, design robustness, precision manufacturing, and effective maintenance, manufacturers can ensure that their Non-Woven Fiber Wheel Production Equipment remains reliable and efficient for years to come. Investing in the durability of Non-Woven Fiber Wheel Production Equipment not only safeguards the environment but also bolsters the bottom line by reducing downtime and maintenance costs.

Twist Wire Pen-Type Wire Brush: Compact and Versatile Cleaning Tool The twist wire pen-type wire brush is a compact, han...

See Details

The Curved Brush Chip Cleaning Machine is engineered to solve common challenges in chip manufacturing, where cleanliness...

See Details

The CNC hydraulic cutting machine is a highly efficient, automated system designed to provide precision cutting for vari...

See Details

A polishing wire brush is an essential tool used in a variety of industries for achieving a smooth, polished surface on ...

See Details+86-18867586928

Contact Us